Woven Multi-Function Fabric Inspection Machine: Enhancing Quality Control In Textile Manufacturing

Are you ready to revolutionize the way quality control is conducted in textile manufacturing? Introducing the Woven Multi-Function Fabric Inspection Machine! This cutting-edge technology is poised to enhance efficiency and accuracy in the production process, ultimately improving the overall quality of textile products. Join us as we delve into the incredible benefits of this innovation and how it is reshaping the industry standards for quality control.

- Importance of Quality Control in Textile Manufacturing

Textile manufacturing is a complex process that involves countless variables, from the type of fabric being used to the intricacies of the weaving and finishing processes. One crucial aspect of ensuring the high quality of textile products is quality control. Quality control in textile manufacturing is essential to ensure that the final products meet the desired standards of durability, appearance, and performance.

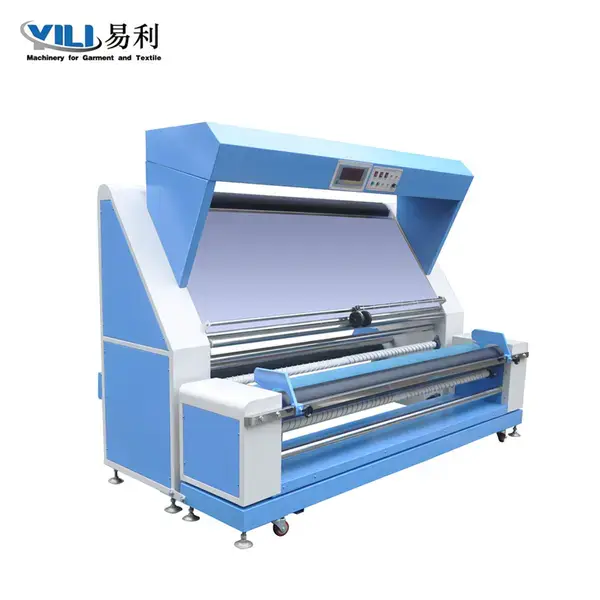

One of the key components of quality control in textile manufacturing is the use of specialized machinery such as the woven multi-function fabric inspection machine. This advanced piece of equipment plays a crucial role in enhancing the quality control process by providing accurate and detailed inspections of woven fabrics. The woven multi-function fabric inspection machine is designed to detect and highlight any imperfections or defects in the fabric, allowing manufacturers to identify and rectify issues before the fabric is used in the production of garments or other textile products.

The woven multi-function fabric inspection machine is a highly versatile piece of equipment that can be used to inspect a wide range of fabrics, including cotton, silk, polyester, and more. It uses a combination of advanced technology, such as high-resolution cameras and sensors, to scan the fabric for defects such as stains, holes, uneven weaving, and other issues. The machine provides a detailed report on the quality of the fabric, allowing manufacturers to make informed decisions about the use of the fabric in their production processes.

One of the key benefits of using a woven multi-function fabric inspection machine is the ability to improve the overall quality of textile products. By detecting and addressing defects early in the manufacturing process, manufacturers can ensure that their products meet the highest standards of quality and durability. This not only enhances the reputation of the brand but also reduces the risk of costly recalls or returns due to substandard products.

Furthermore, the use of a woven multi-function fabric inspection machine can also help manufacturers increase efficiency and reduce waste in their production processes. By identifying defects quickly and accurately, manufacturers can take corrective action before the fabric is used in production, reducing the amount of rework or scrap material that is generated. This not only saves time and resources but also helps to improve overall productivity and profitability.

In conclusion, the woven multi-function fabric inspection machine plays a crucial role in enhancing quality control in textile manufacturing. By providing accurate and detailed inspections of woven fabrics, this advanced piece of equipment helps manufacturers ensure that their products meet the desired standards of quality and durability. With the use of this technology, manufacturers can improve efficiency, reduce waste, and ultimately deliver high-quality textile products to consumers.

- Features of the Woven Multi-Function Fabric Inspection Machine

In the highly competitive textile manufacturing industry, ensuring the quality of fabrics is of utmost importance. This is where the Woven Multi-Function Fabric Inspection Machine comes into play, offering advanced features that enhance quality control processes and improve overall efficiency in fabric inspection.

One of the key features of the Woven Multi-Function Fabric Inspection Machine is its versatility. This machine is designed to inspect various types of woven fabrics, including cotton, polyester, silk, and more. This versatility allows textile manufacturers to use the same machine for different types of fabrics, reducing the need for multiple inspection machines and streamlining the production process.

Another important feature of this machine is its high-speed inspection capabilities. The Woven Multi-Function Fabric Inspection Machine is equipped with advanced sensors and cameras that can detect defects in fabrics at a rapid pace. This high-speed inspection process ensures that fabrics are thoroughly examined for any imperfections, allowing manufacturers to identify and address issues quickly to prevent them from reaching the market.

In addition to speed, this machine also offers precision in fabric inspection. The advanced technology used in the Woven Multi-Function Fabric Inspection Machine allows for the detection of even the smallest defects in fabrics, such as holes, stains, or irregularities in the weave. This level of precision ensures that only high-quality fabrics are approved for further processing, reducing the risk of producing subpar products.

Furthermore, the Woven Multi-Function Fabric Inspection Machine is equipped with user-friendly software that allows operators to easily control the inspection process. The intuitive interface of the software enables operators to set parameters, adjust inspection settings, and analyze inspection results with ease. This user-friendly feature helps to streamline the fabric inspection process and reduce the likelihood of human error.

Moreover, the Woven Multi-Function Fabric Inspection Machine is designed for durability and reliability. This machine is built using high-quality materials and components that are designed to withstand the rigorous demands of textile manufacturing. Its robust construction ensures that the machine operates smoothly and consistently, providing reliable performance even in high-volume production environments.

Overall, the Woven Multi-Function Fabric Inspection Machine is a game-changer in the textile manufacturing industry. Its advanced features, including versatility, high-speed inspection capabilities, precision, user-friendly software, and durability, make it an invaluable tool for enhancing quality control processes in fabric inspection. With this machine, textile manufacturers can ensure that only top-quality fabrics reach the market, ultimately improving customer satisfaction and boosting their reputation in the industry.

- How the Machine Enhances Efficiency in Textile Manufacturing

In today's fast-paced textile industry, quality control is crucial to ensuring that products meet the high standards demanded by consumers. One innovative solution that has revolutionized the way textiles are inspected is the Woven Multi-Function Fabric Inspection Machine. This cutting-edge technology has transformed the way textiles are examined, allowing for greater efficiency and accuracy in the manufacturing process.

The Woven Multi-Function Fabric Inspection Machine is a state-of-the-art piece of equipment that has been specifically designed to enhance quality control in textile manufacturing. This machine is equipped with advanced features that allow for thorough inspection of fabrics, ensuring that any defects or imperfections are quickly identified and rectified. By utilizing a combination of sensors, cameras, and software algorithms, this machine can detect even the smallest flaws in fabric, ensuring that only the highest quality textiles are produced.

One of the key benefits of the Woven Multi-Function Fabric Inspection Machine is its ability to enhance efficiency in the manufacturing process. Traditionally, inspecting fabrics for defects was a time-consuming and labor-intensive task that required a keen eye and attention to detail. With the introduction of this machine, manufacturers can now streamline the inspection process, allowing for greater productivity and faster turnaround times. This not only speeds up production but also helps to reduce costs associated with manual inspection methods.

Another important feature of the Woven Multi-Function Fabric Inspection Machine is its versatility. This machine is capable of inspecting a wide range of fabrics, from delicate silks to heavy-duty denim, making it suitable for use across a variety of textile manufacturing processes. Whether it's checking for color consistency, pattern alignment, or fabric strength, this machine can handle it all with precision and accuracy.

Furthermore, the Woven Multi-Function Fabric Inspection Machine is equipped with user-friendly controls that make it easy to operate. Manufacturers can customize inspection criteria based on their specific requirements, ensuring that each fabric is thoroughly examined according to their standards. This level of customization not only ensures consistent quality but also allows manufacturers to adapt to changing market demands quickly.

In conclusion, the Woven Multi-Function Fabric Inspection Machine is a game-changer for the textile industry. By enhancing quality control and efficiency in textile manufacturing, this machine has the potential to revolutionize the way fabrics are produced. With its advanced features, versatility, and user-friendly controls, this machine is set to become an indispensable tool for manufacturers looking to stay ahead in a competitive market.

- Benefits of Implementing the Machine in Production Processes

In today's fast-paced and competitive textile manufacturing industry, quality control is of utmost importance. With the increasing demand for high-quality fabrics and garments, manufacturers are constantly seeking ways to enhance their production processes to ensure that their products meet the highest standards. One innovative solution that has been gaining popularity in recent years is the woven multi-function fabric inspection machine.

The woven multi-function fabric inspection machine is a cutting-edge piece of equipment that is revolutionizing the way textile manufacturers conduct quality control checks on their fabrics. This sophisticated machine is designed to detect and identify any imperfections or defects in the fabric, such as misprints, holes, stains, or uneven dyeing. By using advanced technology and sensors, the machine is able to scan the fabric quickly and accurately, providing detailed feedback on the quality of the fabric.

One of the key benefits of implementing a woven multi-function fabric inspection machine in production processes is the significant improvement in quality control. Traditionally, quality control checks were done manually by workers, which was time-consuming and prone to human error. With the introduction of the inspection machine, manufacturers can now conduct quality control checks more efficiently and effectively, ensuring that only high-quality fabrics are passed through the production line.

Another advantage of using a woven multi-function fabric inspection machine is the increase in productivity. By automating the quality control process, manufacturers can save time and resources, allowing them to focus on other important aspects of production. Additionally, the machine can scan large quantities of fabric in a short amount of time, reducing the time it takes to inspect each batch of fabric. This increased efficiency can lead to a faster turnaround time for orders, ultimately benefiting both the manufacturer and the customer.

Furthermore, the woven multi-function fabric inspection machine also helps manufacturers reduce waste and minimize costs. By catching defects early in the production process, manufacturers can avoid producing faulty products that would otherwise need to be discarded or reworked. This not only saves money on materials and labor but also helps minimize the environmental impact of textile production.

In conclusion, the woven multi-function fabric inspection machine is a valuable tool for enhancing quality control in textile manufacturing. By implementing this advanced technology in production processes, manufacturers can improve the quality of their fabrics, increase productivity, reduce waste, and ultimately provide customers with high-quality products that meet their expectations. As the textile industry continues to evolve and demand for quality products grows, the woven multi-function fabric inspection machine will play a crucial role in ensuring that manufacturers stay competitive and meet the demands of the market.

- Future Trends in Quality Control Technology for Textile Manufacturing

In today's fast-paced textile manufacturing industry, ensuring high-quality products is more important than ever. With advancements in technology, manufacturers are constantly seeking innovative ways to improve their quality control processes. One of the latest trends in quality control technology for textile manufacturing is the development of woven multi-function fabric inspection machines.

These cutting-edge machines are designed to enhance the quality control process by providing a comprehensive analysis of fabric defects and inconsistencies. By utilizing advanced imaging technology, these machines are able to detect even the smallest imperfections in the fabric, such as holes, stains, or inconsistencies in color or texture.

One of the key benefits of using a woven multi-function fabric inspection machine is the ability to increase productivity and efficiency in the manufacturing process. By quickly identifying and addressing any defects in the fabric, manufacturers can reduce the amount of rework needed and minimize waste. This ultimately leads to a more cost-effective production process and higher quality products for consumers.

Additionally, these machines can help manufacturers improve their overall production quality by providing real-time feedback and data analysis. By collecting and analyzing data on fabric defects and inconsistencies, manufacturers can identify patterns and trends that may be impacting the quality of their products. This information can then be used to make informed decisions on how to improve their manufacturing processes and address any underlying issues.

Woven multi-function fabric inspection machines are also capable of performing a variety of functions beyond just defect detection. Some machines are equipped with additional features, such as automatic cutting and trimming capabilities, which can further streamline the manufacturing process and improve overall efficiency.

Overall, the development of woven multi-function fabric inspection machines represents an exciting advancement in quality control technology for textile manufacturing. By incorporating these machines into their production processes, manufacturers can significantly improve the quality of their products, increase efficiency, and ultimately satisfy consumer demand for high-quality textiles. As technology continues to advance, we can expect to see even more innovative solutions emerge in the realm of quality control for textile manufacturing.

Conclusion

In conclusion, the Woven Multi-Function Fabric Inspection Machine has proven to be a valuable tool in enhancing quality control in textile manufacturing. By providing a comprehensive and efficient way to inspect fabrics for defects, this machine has helped companies improve their production processes and deliver higher quality products to their customers. With its advanced technology and user-friendly design, it is clear that this machine is a game-changer in the textile industry. As manufacturing standards continue to rise, investing in such innovative solutions will be essential for companies looking to stay competitive in the global market. The future of textile manufacturing looks brighter with the implementation of this groundbreaking machine.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.