The Art Of Fusion: Exploring The World Of Fusing Machines

In the fast-paced world of textile and fashion manufacturing, the art of fusion is a crucial technique that can make or break the quality and durability of a product. Fusing machines play a pivotal role in this process, seamlessly combining fabrics and materials to create seamless and long-lasting results. Join us as we delve into the fascinating world of fusing machines, exploring their capabilities, benefits, and the innovative technology shaping the future of this essential industry. Whether you're a seasoned professional or a curious newcomer, prepare to be amazed by the intricate and meticulous art of fusion.

- Understanding the Concept of Fusion in Machinery

In the world of machinery, the concept of fusion plays a crucial role in the function and efficiency of various equipment. From industrial to domestic settings, fusing machines are utilized in a wide range of applications to bond materials together seamlessly. This article will delve into the intricate details of fusing machines, shedding light on the art of fusion and exploring the fascinating world of machinery.

Fusing machines are designed to merge two or more materials by applying heat, pressure, or both. The process involves melting the materials at their interface, allowing them to mix and form a strong bond when cooled down. This technique is commonly used in industries such as textiles, electronics, and automotive, where precise and durable bonding is essential.

One of the key components of a fusing machine is the heating element, which generates the necessary heat to melt the materials. These elements can vary in type, from infrared to hot air, depending on the specific requirements of the application. The temperature and pressure settings of the machine also play a vital role in determining the quality of the fusion process.

In the textile industry, fusing machines are used to bond fabrics together, creating seamless seams and reinforcing garment structures. The heat and pressure applied by the machine ensure a strong bond that is resistant to wear and tear. This process is crucial in the production of high-quality garments and accessories.

In the electronics industry, fusing machines are utilized to connect components on circuit boards, ensuring reliable electrical connections. The precise control of temperature and pressure is essential in this application to prevent damage to delicate electronic components. The fusion process in electronics manufacturing plays a crucial role in ensuring the functionality and longevity of the final product.

In the automotive industry, fusing machines are employed in the assembly of vehicle parts, such as plastic panels and trim pieces. The seamless bonding provided by these machines enhances the aesthetics and durability of the vehicle, contributing to a superior finish. The efficiency and precision of fusing machines have revolutionized the production processes in the automotive sector, leading to higher quality and productivity.

Overall, fusing machines represent the pinnacle of engineering and innovation in the world of machinery. Their ability to merge materials seamlessly and efficiently has revolutionized various industries, from textiles to electronics to automotive. The art of fusion in machinery is a testament to human ingenuity and technological advancement, showcasing the endless possibilities of modern manufacturing processes.

- Types of Fusing Machines Available in the Market

Fusing machines have become an integral part of the textile industry, playing a crucial role in the production of garments, home textiles, and other fabrics. These innovative machines utilize heat and pressure to bond fabrics together, eliminating the need for traditional sewing methods. In this article, we will explore the world of fusing machines, focusing on the different types available in the market.

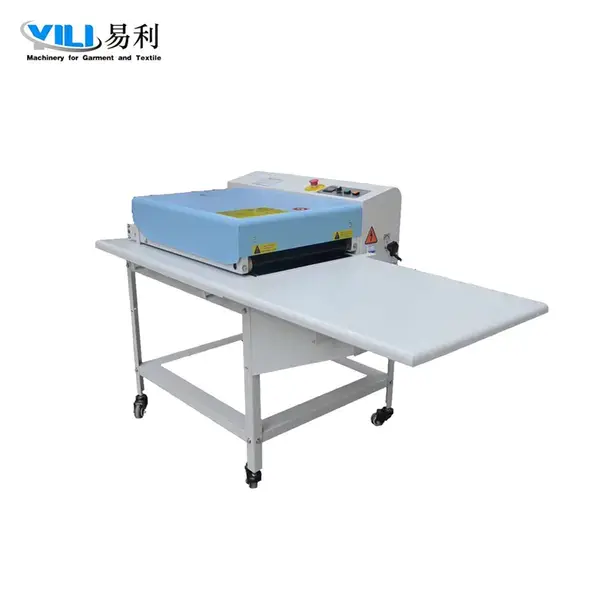

One of the most common types of fusing machines is the flatbed fusing machine. This type of machine features a flat pressing surface where fabrics are placed for bonding. The heat and pressure are applied evenly across the fabric, ensuring a strong and durable bond. Flatbed fusing machines are ideal for fusing smaller pieces of fabric and are commonly used in garment manufacturing.

Another popular type of fusing machine is the rotary fusing machine. This machine features a rotating drum that allows fabrics to be continuously fed through for fusing. The rotary fusing machine is ideal for high volume production as it can process fabrics at a faster pace compared to flatbed machines. This type of machine is often used in large-scale garment manufacturing facilities.

In addition to flatbed and rotary fusing machines, there are also specialized machines available in the market. For example, there are fusing machines specifically designed for knits and stretch fabrics. These machines are equipped with adjustable settings to ensure that the elasticity of the fabric is maintained during the fusing process. There are also fusing machines that are designed for delicate fabrics, ensuring that they are not damaged during the bonding process.

When choosing a fusing machine, it is important to consider the size and type of fabrics you will be working with. For smaller garments or home textiles, a flatbed fusing machine may be sufficient. However, if you are working with larger volumes of fabric or specialized materials, a rotary fusing machine may be more suitable.

It is also important to consider the features and capabilities of the fusing machine. Some machines offer programmable settings, allowing for precise control over the temperature and pressure during the fusing process. Others may have additional features such as cooling fans or automatic shut-off functions for added safety.

In conclusion, fusing machines have revolutionized the way fabrics are bonded together in the textile industry. With a variety of types available in the market, there is a fusing machine to suit every need and requirement. Whether you are a small-scale garment maker or a large-scale manufacturer, investing in a quality fusing machine can help improve the efficiency and quality of your production processes.

- How Fusing Machines Have Revolutionized Various Industries

Fusing machines have indeed revolutionized various industries, bringing about a new era of efficiency and precision in manufacturing processes. These machines are a critical component in the production of a wide range of products, from clothing to automotive parts to electronics. In this article, we will delve into the world of fusing machines, exploring the technology, applications, and impact they have had on industries around the globe.

Fusing machines are a type of equipment that uses heat and pressure to bond two materials together. These materials can range from fabrics to plastics to metals, and the process of fusing them together creates a strong, durable bond that is essential in the manufacturing of high-quality products. The use of fusing machines eliminates the need for traditional sewing or adhesive methods, saving time and labor costs while also ensuring consistent and reliable results.

One of the key applications of fusing machines is in the textile industry, where they are used to create seamless and durable seams in garments and other textile products. By fusing fabrics together, manufacturers can produce high-quality clothing items that are both stylish and long-lasting. Fusing machines have also revolutionized the production of automotive interiors, as they are used to bond different materials together to create upholstery, headliners, and other interior components that are both aesthetically pleasing and durable.

In the electronics industry, fusing machines play a crucial role in the manufacturing of circuit boards and other electronic components. These machines are used to bond layers of materials together to create the intricate patterns and connections needed for electronic devices to function properly. The precise control and high temperatures of fusing machines ensure that the bonds created are strong and reliable, essential for the performance of electronic products.

The impact of fusing machines extends beyond just these industries, however. They have also been instrumental in the production of medical devices, aerospace components, and even food packaging. The versatility and efficiency of fusing machines have made them an indispensable tool in modern manufacturing processes, helping companies produce high-quality products quickly and cost-effectively.

As technology continues to advance, the capabilities of fusing machines will only continue to improve. New innovations in materials, processes, and automation are constantly being developed, expanding the potential applications of these machines even further. In conclusion, fusing machines have truly revolutionized various industries, providing manufacturers with a powerful tool to create high-quality products efficiently and effectively.

- Important Considerations When Choosing a Fusing Machine

Fusing machines are an essential tool in the world of textile and garment manufacturing, as they are used to join fabrics together using heat and pressure. When choosing a fusing machine, there are several important considerations that need to be taken into account to ensure that you select the right machine for your specific needs.

One of the first things to consider when choosing a fusing machine is the type of fabrics you will be working with. Different fabrics require different heat and pressure settings, so it is important to choose a machine that can accommodate the materials you will be using. For example, lightweight fabrics such as silk and chiffon require lower heat and pressure settings, while heavier fabrics like denim and canvas require higher heat and pressure settings.

Another important consideration when choosing a fusing machine is the size and capacity of the machine. If you will be working with large quantities of fabric or larger pieces of fabric, you will need a machine with a larger workspace and higher capacity. On the other hand, if you will be working on smaller projects or with smaller pieces of fabric, a smaller machine may be more suitable.

Additionally, it is important to consider the features and capabilities of the fusing machine. Some machines come with adjustable heat and pressure settings, automatic temperature control, and pre-programmed settings for different types of fabrics. These features can make it easier to achieve the desired results and ensure that the fusing process is consistent and reliable.

It is also important to consider the brand and reputation of the fusing machine manufacturer. Some brands are known for their high-quality machines and reliable performance, while others may have a reputation for lower quality machines that are prone to breaking down. Doing research on the different brands and reading reviews from other users can help you make an informed decision when choosing a fusing machine.

In conclusion, choosing the right fusing machine is essential for achieving high-quality results in textile and garment manufacturing. By considering factors such as the type of fabrics you will be working with, the size and capacity of the machine, its features and capabilities, and the brand and reputation of the manufacturer, you can ensure that you select a machine that meets your specific needs and requirements. Whether you are a seasoned professional or just starting out in the world of fusing machines, taking the time to carefully consider these important factors will help you achieve success in your fusing projects.

- Exploring the Future Possibilities of Fusion Technology in Machinery

Fusion technology has long been at the forefront of innovation in the world of machinery. From the fusion of metals to the fusion of fabrics, this cutting-edge technology has revolutionized the way we create and manipulate materials. In this article, we will delve into the exciting world of fusing machines and explore the future possibilities that this technology holds.

At its core, a fusing machine is a device that uses heat and pressure to bond two materials together. This process is commonly used in industries such as textile manufacturing, automotive, and electronics, where a strong and reliable bond is crucial. Fusing machines come in various shapes and sizes, from small hand-held devices to large industrial machines capable of handling massive volumes of materials.

One of the key advantages of fusing machines is their ability to create seamless bonds between materials. Unlike traditional bonding methods such as sewing or adhesive bonding, fusing machines can create a bond that is both strong and durable without the need for additional materials. This not only results in a cleaner and more professional finish but also improves the overall quality and longevity of the final product.

The future possibilities of fusion technology in machinery are vast and exciting. As technology continues to advance, we can expect to see fusing machines that are faster, more efficient, and capable of working with a wider range of materials. Imagine a fusing machine that is able to bond not just fabrics, but also metals, plastics, and even composites. This would open up a whole new world of possibilities for manufacturers, allowing them to create products that are stronger, lighter, and more versatile than ever before.

Another exciting development in fusion technology is the integration of artificial intelligence (AI) and machine learning systems into fusing machines. These intelligent systems can optimize the fusing process, making real-time adjustments to temperature, pressure, and other variables to ensure the perfect bond every time. This not only improves the efficiency of the fusing process but also reduces waste and helps to lower production costs.

In conclusion, fusing machines represent the cutting edge of fusion technology in machinery. With their ability to create strong and durable bonds between materials, they have revolutionized industries ranging from textiles to automotive. As technology continues to advance, we can expect to see even more exciting developments in this field, with fusing machines that are faster, more efficient, and capable of working with a wider range of materials. The future of fusion technology in machinery is bright, and the possibilities are endless.

Conclusion

In conclusion, fusing machines have revolutionized the way fabrics are joined together, opening up a world of possibilities for designers and manufacturers. With their ability to seamlessly bond materials and create strong, durable seams, fusing machines have become an indispensable tool in the fashion and textile industries. By exploring the world of fusing machines, we have uncovered the art of fusion - a delicate balance of precision, creativity, and technology. As we continue to push the boundaries of innovation, fusing machines will undoubtedly play a key role in shaping the future of fabric joining techniques. So whether you're a seasoned professional or a curious newcomer, dive into the world of fusing machines and unlock the endless possibilities that await.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.