Revolutionizing Textile Production: The Woven Fabric Rolling Machine

Innovations in technology have continually transformed the textile industry, making production faster, more efficient, and more cost-effective. One such groundbreaking invention is the Woven Fabric Rolling Machine, which has revolutionized the way textiles are produced. This article delves into the functionalities and benefits of this game-changing machine, and how it is reshaping the future of textile production. Join us as we explore the impact of this innovative technology on the textile industry and discover the endless possibilities it offers.

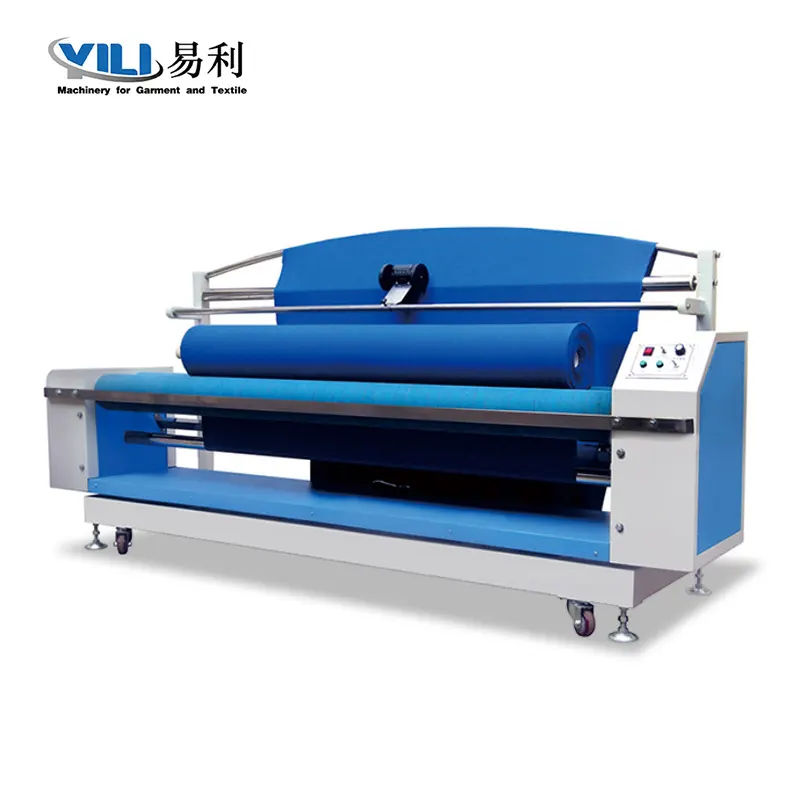

- Introducing the Woven Fabric Rolling Machine

In the fast-paced world of textile production, efficiency is key. Manufacturers are constantly looking for ways to streamline their processes and increase output without sacrificing quality. Enter the Woven Fabric Rolling Machine - a game-changing innovation that is set to revolutionize the industry.

The Woven Fabric Rolling Machine is a state-of-the-art piece of equipment that is designed to automate the process of rolling woven fabric. Traditionally, this task has been done manually, requiring a team of workers to handle large rolls of fabric and roll them up by hand. This is not only time-consuming but also physically demanding work. The Woven Fabric Rolling Machine eliminates the need for manual labor, allowing manufacturers to increase their production capacity and reduce labor costs.

One of the key features of the Woven Fabric Rolling Machine is its speed and efficiency. This machine can roll fabric at a much faster rate than any human worker, allowing manufacturers to meet tight deadlines and fulfill large orders in a fraction of the time. This increased efficiency also translates to cost savings, as manufacturers can produce more fabric in less time, resulting in higher profits.

Another advantage of the Woven Fabric Rolling Machine is its consistency and precision. Manual rolling can often result in uneven rolls or creases in the fabric, leading to quality issues and wasted material. The Woven Fabric Rolling Machine ensures that every roll is perfectly uniform, with no wrinkles or imperfections. This not only improves the overall quality of the fabric but also reduces waste, saving manufacturers money in the long run.

The Woven Fabric Rolling Machine is also incredibly versatile, able to handle a wide range of fabric types and sizes. Whether you are working with delicate silk or heavy-duty canvas, this machine can handle it all with ease. It can also be easily adjusted to accommodate different roll sizes, making it a flexible solution for manufacturers with varying production needs.

Overall, the Woven Fabric Rolling Machine is a game-changer for the textile industry. Its speed, efficiency, consistency, and versatility make it an invaluable tool for manufacturers looking to take their production to the next level. With this innovative machine, the future of textile production looks brighter than ever.

- Benefits of Automating Textile Production

The textile industry has always been a vital sector of the economy, contributing significantly to both GDP and employment levels. With the advancement of technology, there has been a constant drive to enhance efficiency in textile production processes. One such innovation that has revolutionized the industry is the woven fabric rolling machine.

The benefits of automating textile production with the implementation of a woven fabric rolling machine are numerous. Firstly, these machines are capable of handling large quantities of fabric in a fraction of the time compared to manual labor. This increase in production output leads to a significant reduction in lead times, allowing textile manufacturers to fulfill orders faster and more efficiently.

Moreover, the precision and consistency provided by woven fabric rolling machines ensure that each roll of fabric meets the desired quality standards. This level of accuracy is crucial in maintaining the integrity of the fabric and ultimately, the final product. By eliminating human error, manufacturers can guarantee a consistent product that meets customer expectations every time.

In addition, the automation of textile production through the use of woven fabric rolling machines also leads to a reduction in labor costs. With fewer workers needed to operate the machines, manufacturers can reallocate resources to other areas of the production process, ultimately increasing overall efficiency and profitability.

Furthermore, these machines are equipped with advanced technology that allows for customization and flexibility in production. Manufacturers can easily adjust settings to accommodate different types of fabric, widths, and lengths, providing a versatile solution for a variety of production needs.

The environmental benefits of automating textile production with woven fabric rolling machines should also not be overlooked. By reducing the amount of waste generated during the production process, manufacturers can minimize their environmental impact and contribute to sustainable practices within the industry.

Overall, the implementation of woven fabric rolling machines in textile production represents a significant step towards modernizing the industry. By embracing automation and technology, manufacturers can streamline their operations, increase productivity, and deliver high-quality products to their customers in a timely manner.

In conclusion, the benefits of automating textile production with woven fabric rolling machines cannot be overstated. From increased efficiency and cost savings to improved quality and sustainability, these machines are truly revolutionizing the way textiles are manufactured. As the industry continues to evolve, it is clear that automation will play a crucial role in shaping the future of textile production.

- How the Machine Improves Efficiency and Quality

In the dynamic and evolving world of textile production, efficiency and quality are paramount. With the introduction of the woven fabric rolling machine, industries are experiencing a revolution in how textiles are produced. This innovative machine has transformed the way fabrics are rolled and stored, leading to improved efficiency and higher quality products.

The woven fabric rolling machine is a game-changer in the textile industry. Gone are the days of manual rolling, which was not only time-consuming but also prone to errors. With this machine, fabric rolls are now produced in a fraction of the time it used to take, allowing for faster production and increased output. This increased efficiency translates to cost savings for manufacturers and faster turnaround times for customers.

One of the key features of the woven fabric rolling machine is its ability to roll fabrics with precision and consistency. This ensures that every roll produced is of the same high quality, eliminating variations in tension and alignment that can occur with manual rolling. The result is a more uniform and reliable product, which is crucial in the textile industry where consistency is key.

Another advantage of the woven fabric rolling machine is its versatility. It can be used with a wide range of fabrics, from delicate silks to heavy-duty denims, making it suitable for a variety of textile production processes. This flexibility allows manufacturers to streamline their operations and adapt to changing market demands without having to invest in multiple machines.

In addition to improving efficiency and quality, the woven fabric rolling machine also offers benefits in terms of ergonomics and safety. Manual rolling can be physically demanding and repetitive, leading to potential injuries for workers. By automating the rolling process, the machine helps to alleviate strain on workers and reduce the risk of injuries. This not only improves worker morale and productivity but also saves on healthcare costs for manufacturers.

Overall, the woven fabric rolling machine is a game-changer in the textile industry, revolutionizing the way fabrics are produced. Its ability to improve efficiency, quality, and worker safety make it a valuable asset for manufacturers looking to stay ahead in a competitive market. As technology continues to advance, we can expect to see even more innovations in textile production that will further enhance the industry.

- Impact on the Textile Industry

In recent years, the textile industry has seen significant advancements in technology that have revolutionized the production process. One such innovation that has had a major impact on the industry is the woven fabric rolling machine. This machine has completely changed the way fabrics are rolled and stored, making the process much more efficient and cost-effective. In this article, we will take a closer look at how the woven fabric rolling machine has transformed the textile industry.

The woven fabric rolling machine is a sophisticated piece of equipment that automates the process of rolling large bolts of fabric. Traditionally, this process was done manually, with workers rolling the fabric by hand onto cardboard tubes. This method was not only time-consuming but also prone to errors and inconsistencies. The woven fabric rolling machine, on the other hand, is able to roll fabric quickly and accurately, ensuring that each bolt is rolled to the exact specifications required by the customer.

One of the key advantages of the woven fabric rolling machine is its ability to increase production efficiency. By automating the rolling process, textile manufacturers are able to roll fabric much faster than before, resulting in higher output levels and reduced lead times. This not only benefits the manufacturers themselves but also has a positive impact on the entire supply chain, as faster production times mean quicker turnaround for customers.

In addition to increasing production efficiency, the woven fabric rolling machine also helps to improve the quality of the finished product. By rolling fabric automatically, the machine ensures that each bolt is rolled evenly and tightly, reducing the risk of wrinkles, creases, and other imperfections. This results in a higher-quality product that is more appealing to customers and ultimately leads to increased sales and revenue for textile manufacturers.

Another significant impact of the woven fabric rolling machine on the textile industry is its ability to reduce waste. The machine is able to roll fabric more efficiently than manual methods, resulting in less material being wasted during the production process. This not only helps to lower production costs but also has a positive environmental impact, as less fabric waste means less material ending up in landfills.

Overall, it is clear that the woven fabric rolling machine has had a profound impact on the textile industry. From increasing production efficiency and improving product quality to reducing waste and lowering costs, this innovative piece of equipment has transformed the way fabrics are rolled and stored. As technology continues to advance, it is likely that we will see further innovations in textile production that build upon the success of the woven fabric rolling machine.

- Future Innovations in Fabric Rolling Technology

In today's rapidly advancing textile industry, the need for efficient and innovative fabric rolling technology is becoming more imperative than ever before. As manufacturers strive to meet the growing demand for high-quality textile products, the development of cutting-edge equipment such as the woven fabric rolling machine is revolutionizing the production process and redefining industry standards.

The woven fabric rolling machine represents a significant leap forward in textile production technology, offering a range of advanced features and capabilities that are poised to transform the way fabrics are processed and rolled. By incorporating state-of-the-art automation and precision engineering, this machine streamlines the rolling process, reducing manual labor and increasing productivity. With the ability to handle a wide variety of fabrics, from lightweight chiffon to heavy denim, the woven fabric rolling machine is versatile and adaptable to meet the needs of diverse textile manufacturers.

One of the key innovations of the woven fabric rolling machine is its advanced control system, which allows for precise and consistent tensioning of the fabric as it is rolled. This not only ensures that the fabric is rolled neatly and evenly, but also minimizes the risk of creases, wrinkles, and other defects that can affect the quality of the final product. Additionally, the machine's automated cutting and trimming functions further enhance efficiency and accuracy, allowing for seamless integration into existing production processes.

In terms of performance, the woven fabric rolling machine delivers exceptional speed and reliability, with the ability to roll large quantities of fabric quickly and efficiently. This high throughput capacity makes it an ideal solution for textile manufacturers looking to increase their output and reduce lead times without compromising on quality. Furthermore, the machine's energy-efficient design helps to reduce operational costs and environmental impact, making it a sustainable choice for modern textile production facilities.

Beyond its technical capabilities, the woven fabric rolling machine also offers a range of practical benefits for manufacturers. Its compact and ergonomic design makes it easy to install and operate, while its user-friendly interface allows for simple and intuitive control. Moreover, the machine's robust construction and durable components ensure long-term durability and reliability, providing a solid investment for businesses looking to enhance their production capabilities.

Overall, the woven fabric rolling machine represents a paradigm shift in textile production technology, setting new standards for efficiency, reliability, and quality in the industry. As manufacturers continue to embrace automation and innovation to stay competitive in the global market, this cutting-edge machine is poised to play a central role in shaping the future of fabric rolling and revolutionizing the way textiles are produced. With its advanced features, superior performance, and practical benefits, the woven fabric rolling machine truly stands at the forefront of future innovations in fabric rolling technology.

Conclusion

In conclusion, the Woven Fabric Rolling Machine has truly revolutionized textile production in a way that is both efficient and innovative. By streamlining the process of rolling woven fabrics, this machine has not only increased productivity, but also reduced labor costs and minimized errors. Its impact on the industry is undeniable, as more and more manufacturers are incorporating this technology into their production lines. With its many benefits and advantages, it is clear that the Woven Fabric Rolling Machine is a game-changer in the world of textile production. As we continue to embrace advancements in technology, it is exciting to envision what other groundbreaking innovations will shape the future of this industry.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.