Unveiling The Magic Of Fabric Shrinking Machines: How They Transform Textiles

Are you curious about how fabric shrinking machines work their magic on textiles? In this article, we will delve into the fascinating world of fabric shrinking machines and explore how they can transform textiles in innovative ways. Join us as we uncover the secrets behind the process and discover the amazing results that can be achieved through this revolutionary technology. Let's unveil the magic of fabric shrinking machines together!

- Understanding the Process: What Fabric Shrinking Machines Do

In the world of textiles, fabric shrinking machines play a crucial role in transforming raw materials into the final products that consumers love. These machines are marvels of modern technology, designed to carefully manipulate fabrics in order to achieve the desired shrinkage levels. In this article, we will dive deep into the process of fabric shrinking machines, exploring how they work and the impact they have on the textile industry.

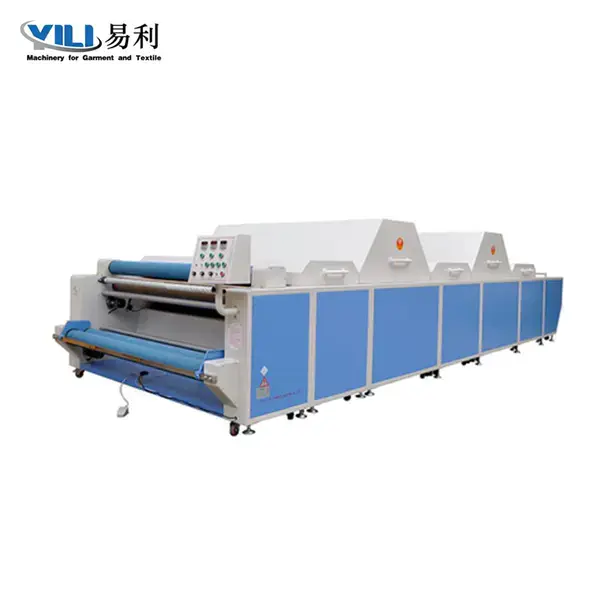

Fabric shrinking machines are specialized devices that use heat and moisture to resize fabrics to their desired dimensions. This process is essential for achieving a uniform appearance and preventing garments from shrinking or stretching further during washing. These machines are typically used in textile factories and garment manufacturing plants, where precision and efficiency are key.

The first step in the fabric shrinking process involves pre-treating the fabric to prepare it for shrinking. This may involve washing the fabric to remove any sizing or finishes that could interfere with the shrinking process. Once the fabric is prepped, it is then fed into the shrinking machine, where it undergoes a series of controlled treatments.

The fabric is exposed to high temperatures and moisture in the shrinking machine, causing the fibers to contract and shrink. The machine carefully monitors and controls the temperature and moisture levels to ensure that the fabric shrinks evenly and to the desired degree. This precise control is crucial for maintaining the quality and integrity of the fabric throughout the shrinking process.

One of the key components of fabric shrinking machines is the conveyor belt system, which carries the fabric through the machine at a consistent speed. This ensures that the fabric is exposed to the heat and moisture evenly, resulting in uniform shrinkage across the entire piece. The conveyor belt system can be adjusted to accommodate different types of fabric and shrinkage levels, making it a versatile tool for manufacturers.

In addition to controlling temperature and moisture levels, fabric shrinking machines may also utilize steam and pressure to further manipulate the fabric. These additional treatments can help to achieve specific textures or finishes, adding value to the final product. The combination of heat, moisture, and pressure in fabric shrinking machines allows manufacturers to create a wide range of effects and finishes, from soft and drapey to crisp and structured.

Overall, fabric shrinking machines are essential tools in the textile industry, helping manufacturers to achieve the desired size and appearance of their fabrics. By understanding the process of fabric shrinking machines and how they work, we can gain a deeper appreciation for the craftsmanship and technology that go into creating the textiles we use every day. From pre-treatment to finishing touches, fabric shrinking machines play a vital role in transforming raw materials into beautiful, wearable garments.

- The Technology Behind the Magic: How Textiles are Transformed

Fabric shrinking machines may seem like magical devices that can transform textiles into unique and innovative designs, but in reality, it is the advanced technology behind these machines that make this transformation possible. In this article, we will delve into the intricate workings of fabric shrinking machines and explore how they are able to completely change the look and feel of various types of fabrics.

One of the key components of fabric shrinking machines is the use of heat and steam. By subjecting the fabric to high temperatures and moisture, the fibers in the fabric are able to relax and contract, resulting in a shrinkage effect. This process is carefully controlled to ensure that the fabric shrinks evenly without causing any damage. The combination of heat and steam is crucial in achieving the desired level of shrinkage and creating unique textures and patterns on the fabric.

Another important aspect of fabric shrinking machines is the use of tension control. By carefully controlling the tension applied to the fabric during the shrinking process, manufacturers are able to achieve precise levels of shrinkage and create intricate designs on the fabric. Tension control is essential in ensuring that the fabric shrinks evenly and consistently, resulting in a high-quality finished product.

In addition to heat, steam, and tension control, fabric shrinking machines also utilize advanced computer technology to monitor and adjust the shrinking process. By using sensors and programmable controls, manufacturers are able to precisely control the temperature, moisture levels, and tension applied to the fabric, ensuring that each piece is shrunk to perfection. This level of automation allows for efficient production and consistent results, making fabric shrinking machines a valuable tool for textile manufacturers.

Furthermore, fabric shrinking machines are capable of producing a wide range of effects on different types of fabrics. From creating unique textures and patterns to completely altering the structure of the fabric, these machines offer endless possibilities for designers and manufacturers to experiment with. Whether it is shrinking wool to create a felt-like material or creating intricate designs on silk fabrics, fabric shrinking machines can transform ordinary textiles into extraordinary works of art.

Overall, fabric shrinking machines represent the perfect blend of technology and craftsmanship. By harnessing the power of heat, steam, tension control, and advanced computer technology, these machines are able to create stunning transformations in textiles that were once thought impossible. With their ability to produce unique textures, patterns, and designs, fabric shrinking machines have become an essential tool for textile manufacturers looking to push the boundaries of creativity and innovation in the industry.

- Benefits of Fabric Shrinking Machines: Why They Are Essential in the Textile Industry

In the vast and intricate world of the textile industry, fabric shrinking machines have become an indispensable tool, revolutionizing the way fabrics are processed and enhancing the overall quality of the end product. These cutting-edge machines are designed to shrink fabrics to precise dimensions, ensuring that they maintain their shape, structure, and integrity.

Fabric shrinking machines offer a plethora of benefits that make them essential in the textile industry. From improving the overall quality and appearance of fabrics to enhancing productivity and efficiency, these machines play a crucial role in transforming textiles and meeting the demands of the ever-evolving market.

One of the key benefits of fabric shrinking machines is their ability to ensure consistent and uniform shrinkage across all types of fabrics. By utilizing advanced technology and innovative design features, these machines are able to shrink fabrics to precise dimensions, eliminating variations in size and shape that can occur during traditional shrinking processes. This level of precision is essential for producing high-quality textiles that meet the exact specifications of designers and manufacturers.

In addition to providing consistent shrinkage, fabric shrinking machines also help to enhance the overall quality and appearance of fabrics. By carefully controlling the shrinkage process, these machines can improve the texture, feel, and drape of fabrics, resulting in a softer, more luxurious end product. This improved quality not only enhances the aesthetic appeal of textiles but also increases their marketability and value.

Another significant benefit of fabric shrinking machines is their ability to increase productivity and efficiency in the textile manufacturing process. By automating the shrinking process, these machines are able to shrink fabrics at a much faster rate than traditional methods, reducing production time and labor costs. This increased efficiency enables manufacturers to meet tight deadlines, fulfill large orders, and stay competitive in a fast-paced industry.

Furthermore, fabric shrinking machines are essential for ensuring that fabrics maintain their shape and structure after repeated wear and washing. By shrinking fabrics to their final dimensions before they are cut and sewn into garments, these machines help to minimize shrinkage in the finished product, prolonging the lifespan of the fabric and ensuring that it retains its original shape and fit over time.

In conclusion, fabric shrinking machines are an essential tool in the textile industry, offering a wide range of benefits that enhance the quality, appearance, and durability of fabrics. By providing precise shrinkage, improving quality, increasing productivity, and maintaining the integrity of fabrics, these machines play a crucial role in transforming textiles and meeting the demands of today's market. As the textile industry continues to evolve and innovate, fabric shrinking machines will undoubtedly remain a cornerstone of the production process, ensuring that fabrics are of the highest quality and meet the exacting standards of designers and consumers alike.

- Exploring Different Types of Fabric Shrinking Machines

Fabric shrinking machines are a vital tool in the textile industry, transforming textiles in ways that were once thought impossible. From pre-shrinking fabrics to creating unique textures and designs, these machines are truly a magical innovation. In this article, we will delve into the world of fabric shrinking machines, exploring the different types available and how they work their wonders on various types of fabrics.

One of the most common types of fabric shrinking machines is the steam shrinking machine. This type of machine uses steam to shrink fabrics, applying heat and moisture to the fabric to cause the fibers to contract. Steam shrinking machines are often used in the production of cotton and wool fabrics, as these fibers are particularly responsive to heat and moisture. The process involves passing the fabric through a steam chamber, where the steam penetrates the fibers and causes them to shrink. This results in a more compact and durable fabric that is less prone to shrinking further in future washes.

Another type of fabric shrinking machine is the mechanical shrinking machine. This machine uses mechanical pressure to shrink fabrics, applying force to the fabric to compress the fibers and reduce their size. Mechanical shrinking machines are often used for fabrics that are resistant to heat and moisture, such as synthetic fabrics like polyester and nylon. The process involves passing the fabric through a series of rollers or plates that apply pressure to the fabric, causing the fibers to shrink and become more compact. This results in a fabric that is more stable and less prone to stretching or warping.

In addition to steam and mechanical shrinking machines, there are also laser shrinking machines that use lasers to shrink fabrics. These machines are particularly popular for creating unique textures and designs in fabrics, as the precision of the laser can be used to selectively shrink certain areas of the fabric. Laser shrinking machines are often used in high-end fashion and designer textiles, where intricate patterns and textures are desired.

Overall, fabric shrinking machines are an essential tool in the textile industry, allowing manufacturers to create fabrics that are more stable, durable, and visually appealing. From steam shrinking machines to mechanical and laser shrinking machines, there are a variety of options available to suit different types of fabrics and production needs. By harnessing the power of these machines, textile manufacturers can transform ordinary fabrics into extraordinary creations that captivate and inspire.

- Future Innovations in Fabric Shrinking Technology: What Lies Ahead

Fabric shrinking machines have been at the forefront of transforming textiles for decades, but with future innovations on the horizon, the possibilities for this technology are endless. From improving efficiency to enhancing the quality of fabrics, the future of fabric shrinking machines looks promising.

One of the key innovations in fabric shrinking technology is the development of more advanced and precise control systems. These control systems allow manufacturers to tailor the shrinking process to specific fabrics, resulting in a more consistent and reliable outcome. By utilizing cutting-edge sensors and software, fabric shrinking machines can detect variations in fabric composition and adjust their settings accordingly, ensuring a perfect shrink every time.

Another exciting development in fabric shrinking technology is the integration of artificial intelligence. With AI-powered algorithms, fabric shrinking machines can learn and adapt to different fabrics, optimizing the shrinking process for maximum efficiency and quality. This advanced technology not only improves productivity but also reduces waste by minimizing errors and ensuring uniform shrinking across all textiles.

In addition to improved control systems and AI integration, future fabric shrinking machines are also expected to incorporate more environmentally friendly features. With a growing focus on sustainability, manufacturers are exploring ways to reduce energy consumption and water usage in the shrinking process. By implementing eco-friendly practices such as heat recovery systems and water recycling, fabric shrinking machines can minimize their environmental impact while still achieving the desired shrinking results.

Moreover, advancements in fabric shrinking technology are also expected to enhance the versatility of these machines. By introducing modular designs and customizable features, manufacturers can adapt fabric shrinking machines to accommodate a wide range of textiles, from delicate silks to heavy-duty denim. This flexibility allows for greater customization and efficiency in the shrinking process, catering to the diverse needs of the textile industry.

Overall, the future of fabric shrinking machines holds great promise for the textile industry. With innovations in control systems, AI integration, sustainability practices, and versatility, these machines are poised to revolutionize the way fabrics are transformed. As manufacturers continue to push the boundaries of technology, we can expect to see even greater advancements in fabric shrinking technology in the years to come.

Conclusion

In conclusion, fabric shrinking machines are truly magical tools that have revolutionized the textile industry. From improving the quality and durability of fabrics to increasing efficiency and reducing waste, these machines play a crucial role in transforming textiles. By understanding how fabric shrinking machines work and the benefits they provide, manufacturers can continue to innovate and create high-quality fabrics for consumers around the world. With their ability to alter the physical properties of textiles, fabric shrinking machines are an essential part of the production process that brings creativity and innovation to the forefront. Embracing these machines is key to unlocking the full potential of textiles and driving the industry forward into a bright and exciting future.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.