Efficiently Shrinking Fabrics With A Small-Scale Machine

Are you tired of wasting time and energy trying to shrink your fabrics manually? Look no further! Our small-scale machine offers an efficient solution for shrinking fabrics with ease. Say goodbye to hours of laborious work and hello to a quick and effective method. Read on to discover how our innovative machine can revolutionize the way you shrink fabrics.

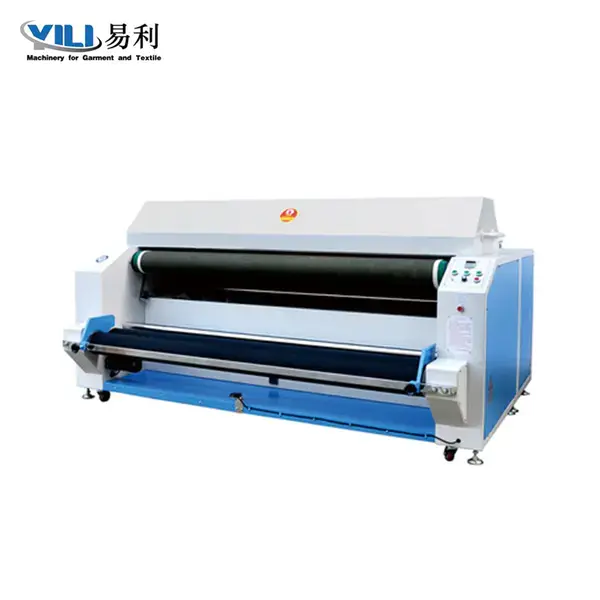

Choosing the Right Small-Scale Machine for Fabric Shrinking

When it comes to shrinking fabrics, finding the right small-scale machine is crucial for achieving efficient results. Whether you are a small business owner or a hobbyist looking to shrink fabrics for various projects, having the right machine can make all the difference. In this article, we will explore the different factors to consider when choosing a small fabric shrinking machine, as well as provide some tips for getting the best results.

One of the most important factors to consider when choosing a small fabric shrinking machine is the type of fabric you will be working with. Different fabrics require different shrinking techniques, so it’s important to choose a machine that is well-suited for the type of fabric you will be working with. For example, if you will be working with delicate fabrics such as silk or lace, you will need a machine that has gentle shrinking capabilities to avoid damaging the fabric.

Another important factor to consider is the size of the machine. Small fabric shrinking machines come in a variety of sizes, so it’s important to choose one that is the right size for your needs. If you will be working with large pieces of fabric, you will need a machine with a larger capacity. On the other hand, if you will be working with smaller pieces of fabric, a smaller machine may be more suitable.

In addition to the size and type of fabric, you should also consider the features and capabilities of the machine. Some small fabric shrinking machines come with adjustable settings that allow you to customize the shrinking process to suit your specific needs. Others may come with additional features such as steam options or multiple shrinking modes. Consider what features are most important to you and choose a machine that meets your requirements.

When using a small fabric shrinking machine, it’s important to follow the manufacturer’s instructions carefully to ensure that you achieve the best results. Start by prepping the fabric according to the machine’s recommendations, and then carefully feed the fabric into the machine. Monitor the shrinking process closely to ensure that the fabric is shrinking evenly and avoid over-shrinking.

In conclusion, choosing the right small fabric shrinking machine is essential for achieving efficient results. Consider factors such as the type of fabric, size of the machine, and features and capabilities when making your decision. By following the manufacturer’s instructions and taking care during the shrinking process, you can achieve professional-quality results with your small-scale machine. Happy fabric shrinking!

Understanding the Process of Fabric Shrinking

Fabrics are an essential part of our daily lives, used in clothing, home decor, and a variety of other applications. However, one common issue that many people face is the shrinkage of fabrics after washing. Understanding the process of fabric shrinking is crucial in order to prevent this from happening. In this article, we will explore how small fabric shrinking machines can efficiently shrink fabrics without causing damage.

When it comes to shrinking fabrics, there are several factors to consider. The primary cause of fabric shrinking is the combination of heat, moisture, and agitation. When fabrics are exposed to these elements, the fibers contract and cause the material to shrink in size. This is why it is important to follow proper care instructions when washing and drying fabrics, as improper treatment can lead to unwanted shrinkage.

Small fabric shrinking machines are designed to mimic the natural shrinking process but on a smaller scale. These machines use controlled heat and steam to shrink fabrics without causing damage. By understanding how these machines work, users can effectively shrink fabrics without risking damage to the material.

One of the key benefits of using a small fabric shrinking machine is the efficiency it offers. Unlike traditional methods of shrinking fabrics, such as boiling or steaming, these machines are quick and easy to use. Simply place the fabric in the machine, set the desired temperature and time, and let the machine do the rest. This not only saves time but also ensures that the fabric is evenly shrunk without any distortion.

Another advantage of small fabric shrinking machines is their versatility. These machines can be used on a wide range of fabrics, from cotton and wool to synthetic blends. This makes them ideal for both personal and professional use, allowing users to shrink fabrics for various projects and applications.

In addition to efficiency and versatility, small fabric shrinking machines also offer precision. Users can set the temperature and time to achieve the desired amount of shrinkage, ensuring that the fabric reaches the perfect size. This level of control is crucial, especially when working on delicate fabrics that require careful handling.

Overall, understanding the process of fabric shrinking is essential for maintaining the quality and longevity of fabrics. Small fabric shrinking machines provide a convenient and effective solution for shrinking fabrics without causing damage. By utilizing these machines, users can efficiently shrink fabrics while preserving their integrity. Whether for personal use or professional applications, small fabric shrinking machines offer a reliable and precise way to achieve the desired results.

Tips for Efficiently Operating a Small-Scale Fabric Shrinking Machine

As the textile industry continues to evolve, small-scale fabric shrinking machines are becoming increasingly popular for both small businesses and hobbyists looking to efficiently shrink fabrics at a smaller scale. This article will provide valuable tips for operating a small fabric shrinking machine effectively, ensuring that you get the best results every time.

One of the most important factors to consider when using a small fabric shrinking machine is the type of fabric you are working with. Different fabrics will require different shrinking techniques, so it is essential to understand the specific properties of the fabric you are working with before getting started. For example, natural fibers like cotton and linen will shrink differently than synthetic fibers like polyester and nylon. By understanding the characteristics of the fabric you are working with, you can adjust the settings on your machine accordingly to achieve the best results.

Another important tip for efficiently operating a small fabric shrinking machine is to pre-treat your fabric before shrinking. Pre-treating involves washing and drying the fabric to remove any dirt, oils, or chemicals that may interfere with the shrinking process. By pre-treating your fabric, you can ensure that it shrinks evenly and consistently, producing a high-quality end result.

When using a small fabric shrinking machine, it is crucial to pay attention to the settings and temperature control. Most machines come with adjustable settings for temperature and shrinkage, allowing you to customize the process based on the type of fabric you are working with. It is essential to follow the manufacturer's instructions closely and test the settings on a small piece of fabric before shrinking a larger piece to ensure that you achieve the desired results.

In addition to temperature control, it is also important to consider the speed at which you feed the fabric through the machine. Too fast or too slow of a feed rate can affect the shrinking process and result in uneven or wrinkled fabric. It is essential to find the right balance and practice with different feed rates to determine the optimal speed for your specific machine and fabric type.

Finally, proper maintenance and cleaning of your small fabric shrinking machine are essential for ensuring its longevity and efficiency. Regularly cleaning the machine and removing any buildup or debris can prevent malfunctions and ensure that it continues to operate smoothly. Additionally, following any maintenance guidelines provided by the manufacturer can help you avoid costly repairs and ensure that your machine stays in optimal condition.

In conclusion, efficiently operating a small fabric shrinking machine requires attention to detail, proper pre-treatment, temperature control, feed rate adjustment, and regular maintenance. By following these tips and guidelines, you can achieve high-quality results and effectively shrink fabrics at a small scale. Whether you are a small business owner or a hobbyist, mastering the art of fabric shrinking with a small-scale machine can help you create beautiful, professional-looking garments and textiles.

Common Mistakes to Avoid When Shrinking Fabrics

When it comes to shrinking fabrics, it is important to use the right techniques and equipment to ensure a successful outcome. Many people make common mistakes when using small-scale machines to shrink fabrics, which can lead to wasted time, money, and effort. In this article, we will discuss some of the most common mistakes to avoid when shrinking fabrics with a small fabric shrinking machine.

One common mistake that people make when using small fabric shrinking machines is not properly prepping the fabric before shrinking. It is important to wash and dry the fabric before shrinking it to remove any excess dirt, oils, or chemicals that could prevent the fabric from shrinking evenly. Additionally, pre-washing the fabric will help to prevent any unwanted shrinkage after the fabric has been shrunk with the machine.

Another common mistake that people make is not following the manufacturer's instructions when using a small fabric shrinking machine. Each machine is different, and it is important to read and understand the instructions provided by the manufacturer to ensure that the fabric is shrunk properly. Failure to follow the instructions could result in uneven shrinking, damage to the fabric, or even damage to the machine itself.

One of the most common mistakes that people make when shrinking fabrics with a small machine is using the wrong temperature or setting. It is important to use the correct temperature and setting for the type of fabric being shrunk to ensure that the fabric shrinks evenly and does not become damaged. Using the wrong temperature or setting could result in the fabric shrinking too much or too little, leaving you with a piece of fabric that is unusable.

Additionally, it is important to be patient when shrinking fabrics with a small-scale machine. Rushing the process or trying to shrink too much fabric at once can lead to uneven shrinking and damage to the fabric. It is best to shrink small amounts of fabric at a time, following the manufacturer's instructions and monitoring the process closely to ensure a successful outcome.

In conclusion, shrinking fabrics with a small fabric shrinking machine can be a simple and efficient process when done correctly. By avoiding common mistakes such as not prepping the fabric properly, not following the manufacturer's instructions, using the wrong temperature or setting, and being patient during the shrinking process, you can achieve great results with your small-scale machine. By taking the time to properly prepare and shrink your fabrics, you can create beautiful, high-quality pieces that will last for years to come.

Maximizing Efficiency and Results with Small-Scale Fabric Shrinking Machines

In the fast-paced world of textile manufacturing, efficiency is key. Maximizing productivity and achieving high-quality results are top priorities for businesses looking to stay ahead of the competition. One essential tool that has revolutionized the way fabrics are processed is the small fabric shrinking machine. These compact, yet powerful machines are designed to efficiently shrink fabrics without compromising on quality.

Small fabric shrinking machines are ideal for businesses with limited space or budget constraints. Despite their size, these machines pack a punch when it comes to performance. They are capable of shrinking a wide variety of fabrics, including cotton, wool, and polyester, with precision and speed. By using advanced technology and innovative design, small fabric shrinking machines are able to achieve consistent results across different fabrics and garment types.

One of the key advantages of small fabric shrinking machines is their ability to save time and labor. Traditional fabric shrinking methods, such as manual steaming or ironing, can be time-consuming and labor-intensive. With a small fabric shrinking machine, fabrics can be processed quickly and efficiently, reducing production time and labor costs. This not only increases productivity but also allows businesses to take on larger orders and meet tight deadlines with ease.

Another benefit of small fabric shrinking machines is their ability to improve the overall quality of the finished product. By using precise heat and steam settings, these machines ensure that fabrics are shrunk evenly and without distortion. This results in a high-quality finish that is free from wrinkles or puckering, making the fabric look professional and polished. In addition, small fabric shrinking machines can also help fabrics retain their original color and texture, giving them a fresh and rejuvenated appearance.

Small fabric shrinking machines are also environmentally friendly. Unlike traditional shrinking methods that rely on chemicals or excessive water consumption, these machines use minimal water and energy to achieve the desired results. This not only reduces the carbon footprint of the manufacturing process but also helps businesses save on utility costs in the long run. By investing in a small fabric shrinking machine, businesses can demonstrate their commitment to sustainability and responsible manufacturing practices.

Overall, small fabric shrinking machines are a game-changer for textile manufacturers looking to maximize efficiency and achieve superior results. These machines combine cutting-edge technology with compact design to deliver exceptional performance, time savings, and quality outcomes. By incorporating a small fabric shrinking machine into their production process, businesses can streamline operations, reduce costs, and elevate the overall quality of their products. In today's competitive market, small fabric shrinking machines are a must-have for any textile manufacturer looking to stay ahead of the curve.

Conclusion

In conclusion, the development of small-scale fabric shrinking machines has revolutionized the textile industry by providing a more efficient and cost-effective method for reducing fabric sizes. Not only does this technology save time and resources, but it also allows for more precise control over the shrinking process, resulting in higher-quality fabrics. With the continued advancements in this field, we can expect to see even more innovations that will further improve the production and quality of textiles. Overall, the future looks promising for the use of small-scale fabric shrinking machines in the textile industry.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.