Maximizing Efficiency: The Benefits Of A Large Fabric Shrinking Machine

Are you tired of spending hours shrinking fabric manually? Say goodbye to wasted time and effort with the revolutionary Large Fabric Shrinking Machine. In our article, we delve into the numerous benefits of this innovative tool and how it can help maximize efficiency in your projects. Read on to discover how this machine can revolutionize your workflow and streamline your production process.

- How a Large Fabric Shrinking Machine Improves Production Efficiency

In the textile industry, efficiency is key to success. Every step of the production process must be optimized to ensure that deadlines are met and costs are kept low. One crucial piece of equipment that is instrumental in maximizing efficiency in the production of textiles is the large fabric shrinking machine.

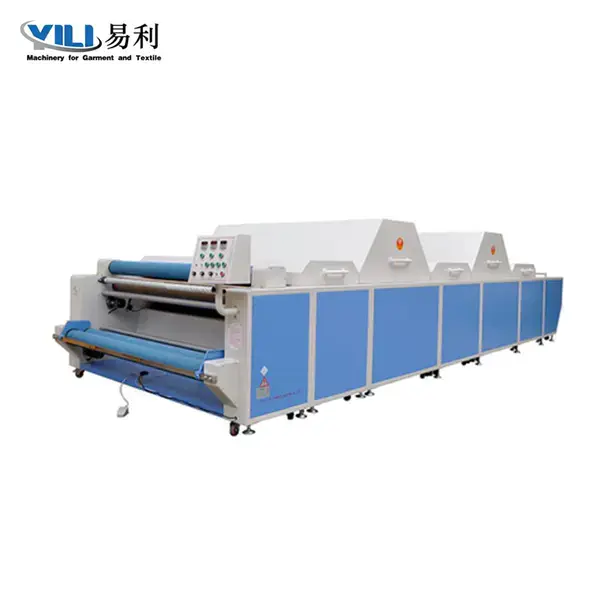

A large fabric shrinking machine is a specialized piece of equipment that is used to pre-treat fabrics before they are cut and sewn. This machine applies heat and moisture to the fabric, causing it to shrink slightly. This process helps to stabilize the fabric and prevent further shrinkage during washing or wearing.

One of the main benefits of using a large fabric shrinking machine is that it improves production efficiency. By pre-treating the fabric before it is cut and sewn, manufacturers can ensure that the fabric will maintain its shape and size throughout the production process. This reduces the risk of errors and rework, saving both time and money.

Another benefit of using a large fabric shrinking machine is that it can help to improve the quality of the finished product. By pre-treating the fabric, manufacturers can ensure that the fabric will not shrink or distort after it has been cut and sewn. This results in a more consistent and professional-looking final product.

In addition to improving production efficiency and product quality, a large fabric shrinking machine can also help to reduce waste. By stabilizing the fabric before it is cut and sewn, manufacturers can minimize the amount of fabric that is discarded due to shrinkage or distortion. This not only saves money on materials but also helps to reduce the environmental impact of production.

Overall, investing in a large fabric shrinking machine can have a significant impact on a textile manufacturer's bottom line. By improving production efficiency, product quality, and waste reduction, this piece of equipment can help manufacturers stay competitive in a fast-paced industry.

In conclusion, a large fabric shrinking machine is a valuable tool for textile manufacturers looking to maximize efficiency in their production process. By pre-treating fabric before it is cut and sewn, manufacturers can improve product quality, reduce waste, and ultimately save time and money. Investing in this technology is a smart decision for any textile manufacturer looking to stay ahead in a competitive market.

- The Cost-Saving Benefits of Using a Large Fabric Shrinking Machine

In the textile industry, maximizing efficiency is crucial for reducing costs and increasing productivity. One way to achieve this is by using a large fabric shrinking machine. These machines offer a range of cost-saving benefits that can make a significant impact on a company's bottom line.

First and foremost, a large fabric shrinking machine can drastically reduce the amount of labor required for the shrinking process. Traditionally, fabric shrinking was done manually, with workers having to carefully control the temperature and humidity levels to achieve the desired results. This process was not only time-consuming but also prone to human error. By using a large fabric shrinking machine, this labor-intensive task can be automated, allowing workers to focus on more important tasks like quality control and production planning.

Another cost-saving benefit of using a large fabric shrinking machine is the reduction in energy consumption. These machines are designed to be energy-efficient, using less electricity and water than traditional shrinking methods. This not only reduces utility costs but also helps companies reduce their carbon footprint, making them more environmentally friendly.

In addition to labor and energy savings, large fabric shrinking machines can also improve the quality and consistency of the shrinking process. These machines are equipped with advanced technology that allows for precise control over temperature, humidity, and shrinkage rate. This ensures that each piece of fabric shrinks uniformly, resulting in a higher-quality end product. Consistency is key in the textile industry, and a large fabric shrinking machine can help companies achieve the level of quality their customers expect.

Furthermore, using a large fabric shrinking machine can also reduce material wastage. When fabric is shrunk manually, there is a higher possibility of errors that can lead to unusable or inconsistent pieces of fabric. This can result in an increase in material wastage, which can be costly for companies. With a large fabric shrinking machine, the shrinking process is controlled and consistent, minimizing the risk of errors and reducing material wastage.

Overall, investing in a large fabric shrinking machine can have a significant impact on a company's efficiency and bottom line. By reducing labor costs, energy consumption, improving quality and consistency, and minimizing material wastage, these machines offer a range of cost-saving benefits that can help companies stay competitive in the fast-paced textile industry. In today's highly competitive market, maximizing efficiency is key, and a large fabric shrinking machine is a valuable tool for achieving that goal.

- Enhancing Quality Control Through Large Fabric Shrinking Machines

In the textile industry, quality control is paramount. Ensuring that fabrics meet the desired specifications is crucial for maintaining customer satisfaction and brand reputation. This is where large fabric shrinking machines come into play. These machines offer a range of benefits that not only maximize efficiency but also enhance quality control processes.

Large fabric shrinking machines utilize advanced technology to effectively shrink and stabilize fabrics, resulting in a more consistent and durable end product. By subjecting fabrics to controlled heat and tension, these machines ensure that shrinkage is minimized and fabric dimensions are maintained. This is particularly important in industries such as fashion and upholstery, where consistency in fabric size and shape is crucial.

One of the key benefits of large fabric shrinking machines is the improvement in quality control. By using these machines, manufacturers can effectively control the shrinkage of fabrics, resulting in a consistent and high-quality product. This consistency is essential for meeting customer expectations and ensuring that fabrics can be used in various applications without fear of shrinkage or distortion.

Moreover, large fabric shrinking machines offer increased efficiency in the production process. These machines are capable of shrinking large quantities of fabric in a relatively short amount of time, thereby streamlining production and reducing lead times. This improved efficiency not only saves time and labor costs but also allows manufacturers to meet tight deadlines and respond quickly to customer demands.

Additionally, large fabric shrinking machines can help reduce waste and improve sustainability in the textile industry. By ensuring that fabrics are properly stabilized and sized, these machines minimize the need for rework or replacement due to shrinkage issues. This not only saves resources but also reduces the environmental impact of textile production.

In conclusion, large fabric shrinking machines offer a range of benefits for manufacturers looking to enhance quality control and efficiency in their production processes. By utilizing these machines, companies can ensure consistent fabric dimensions, reduce waste, and improve sustainability in the textile industry. Ultimately, investing in large fabric shrinking machines is a wise decision for any manufacturer looking to stay competitive in the market.

- Maximizing Floor Space with a Large Fabric Shrinking Machine

In the fast-paced world of textile manufacturing, every square inch of floor space counts. To keep up with increasing demands and competition in the industry, companies are constantly looking for ways to maximize efficiency and productivity. One key solution that has been gaining popularity in recent years is the use of large fabric shrinking machines.

These cutting-edge machines are designed to shrink fabric quickly and efficiently, allowing manufacturers to reduce production time and costs while also maximizing floor space. By utilizing a large fabric shrinking machine, companies can significantly increase their output without having to make major changes to their existing production processes.

One of the biggest benefits of a large fabric shrinking machine is its ability to shrink fabric in large quantities. These machines are capable of handling huge volumes of fabric at once, allowing manufacturers to complete large orders in a fraction of the time it would take using traditional shrinking methods. This not only speeds up production but also helps companies meet tight deadlines and keep up with consumer demand.

In addition to increasing production capacity, large fabric shrinking machines also help companies maximize their use of floor space. By consolidating the shrinking process into a single, efficient machine, manufacturers can free up valuable space on the production floor for other processes or equipment. This not only helps improve workflow and reduce clutter but also allows companies to use their space more effectively, ultimately leading to higher productivity and profitability.

Another key benefit of large fabric shrinking machines is their precision and accuracy. These machines are designed to shrink fabric evenly and consistently, resulting in high-quality finished products that meet strict industry standards. This level of precision is essential for companies looking to maintain a competitive edge in the market and satisfy demanding customers who expect nothing but the best.

Furthermore, large fabric shrinking machines are also highly versatile and customizable, allowing manufacturers to tailor their shrinking process to meet specific production needs and requirements. Whether companies are working with delicate fabrics or heavy-duty materials, these machines can be adjusted to ensure optimal results every time. This flexibility not only helps companies adapt to changing market trends but also allows them to explore new opportunities and expand their product offerings.

Overall, the benefits of a large fabric shrinking machine are clear. From maximizing production capacity to optimizing floor space and ensuring high-quality results, these machines offer a wide range of advantages for textile manufacturers looking to stay ahead in a competitive industry. By investing in this cutting-edge technology, companies can improve efficiency, boost productivity, and ultimately achieve greater success in today's fast-paced marketplace.

- The Environmental Impact of Utilizing Large Fabric Shrinking Machines

In recent years, the fashion and textile industry has seen a significant increase in the use of large fabric shrinking machines. These machines have revolutionized the way fabrics are processed and have led to increased efficiency and productivity in production processes. However, with the rise of these machines comes an important consideration – the environmental impact of utilizing them.

Large fabric shrinking machines are known for their ability to shrink fabric quickly and efficiently, saving time and resources for manufacturers. This increased efficiency can lead to cost savings and faster production timelines, making them an attractive option for many businesses in the industry. However, the environmental impact of using these machines should not be overlooked.

One of the key environmental concerns associated with large fabric shrinking machines is their energy consumption. These machines require a significant amount of electricity to operate, which can lead to increased carbon emissions and contribute to climate change. As the fashion industry continues to be one of the largest contributors to greenhouse gas emissions, finding ways to reduce energy consumption in production processes is crucial.

In addition to energy consumption, large fabric shrinking machines also use chemicals and water in the shrinking process. The chemicals used in these machines can have harmful effects on the environment if not properly managed and disposed of. Likewise, the water used in the process can contribute to water pollution if not treated properly before being released back into the environment.

One way to mitigate the environmental impact of utilizing large fabric shrinking machines is to invest in more sustainable practices and technologies. For example, manufacturers can consider using renewable energy sources to power their machines, such as solar or wind power. They can also look for ways to reduce the use of chemicals in the shrinking process and implement water recycling systems to minimize water waste.

Another important consideration is the lifespan of these machines. By investing in high-quality, durable machines that are built to last, manufacturers can reduce the need for frequent replacements and ultimately reduce their overall environmental footprint.

Overall, while large fabric shrinking machines offer numerous benefits in terms of efficiency and productivity, it is important for manufacturers to also consider the environmental impact of using them. By implementing sustainable practices and technologies, businesses can minimize their carbon footprint and help create a more environmentally friendly industry.

Conclusion

In conclusion, utilizing a large fabric shrinking machine can bring immense benefits to any production facility looking to maximize efficiency. From reducing production time and costs to improving overall quality and consistency, this innovative piece of equipment truly is a game-changer in the textile industry. By investing in a large fabric shrinking machine, businesses can streamline their operations, increase productivity, and ultimately stay ahead of the competition. So, why wait? Upgrade your facility today and experience the numerous advantages that come with implementing this powerful tool.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.