Revolutionizing Textile Quality Control: Introducing The Intelligent Automatic Fabric Inspection Machine

Are you tired of manual fabric inspection processes that are time-consuming and prone to errors? Look no further! Our revolutionary Intelligent Automatic Fabric Inspection Machine is set to transform the way textile quality control is carried out. With cutting-edge technology and intelligent systems, this machine guarantees accurate and efficient inspection, ensuring only the highest quality fabrics make it to market. Discover how this game-changing innovation is revolutionizing the textile industry in our detailed article below.

- The Need for Improved Textile Quality Control

In the fast-paced world of textile manufacturing, the need for improved quality control processes is more crucial than ever. As the demand for high-quality fabrics continues to rise, manufacturers are constantly seeking innovative solutions to ensure that their products meet the strictest of standards. This is where the intelligent automatic fabric inspection machine comes into play.

Traditional methods of fabric inspection often rely on manual labor, which can be time-consuming, labor-intensive, and prone to human error. These methods are also not equipped to handle the growing volume of fabrics being produced in today's textile industry. As a result, manufacturers are turning to automated systems to streamline their quality control processes and improve efficiency.

The intelligent automatic fabric inspection machine is a revolutionary technology that offers a solution to these challenges. By using cutting-edge artificial intelligence and machine learning algorithms, this advanced system can quickly and accurately inspect fabrics for defects, inconsistencies, and imperfections. Unlike human inspectors, the machine is capable of processing large quantities of fabric in a fraction of the time, without sacrificing accuracy or reliability.

One of the key features of the intelligent automatic fabric inspection machine is its ability to detect even the smallest of defects that may go unnoticed by the human eye. With its high-resolution cameras and sophisticated image processing software, the machine can identify imperfections such as color variations, weaving errors, and stitching defects with unparalleled precision. This level of detail ensures that only the highest quality fabrics are sent to market, reducing the risk of customer complaints and returns.

In addition to its impressive accuracy, the intelligent automatic fabric inspection machine also offers significant cost savings for manufacturers. By eliminating the need for manual labor and reducing the number of defective fabrics that make it to market, companies can improve their overall efficiency and productivity. This not only results in higher profits but also enhances their reputation as a reliable and trustworthy provider of quality textiles.

Furthermore, the machine's intelligent automation capabilities allow manufacturers to track and analyze data related to fabric defects over time. By collecting information on the types and frequencies of defects detected, companies can identify patterns and make informed decisions to improve their production processes. This proactive approach to quality control helps to prevent future defects from occurring, resulting in higher customer satisfaction and loyalty.

In conclusion, the intelligent automatic fabric inspection machine is revolutionizing the way textiles are inspected and ensuring that only the highest quality fabrics reach the hands of consumers. With its advanced technology, precision accuracy, and cost-saving benefits, this innovative system is quickly becoming an indispensable tool for manufacturers in the textile industry. By embracing this cutting-edge technology, companies can stay ahead of the competition, meet the demands of a discerning market, and secure their position as leaders in the world of textile manufacturing.

- Introducing the Intelligent Automatic Fabric Inspection Machine

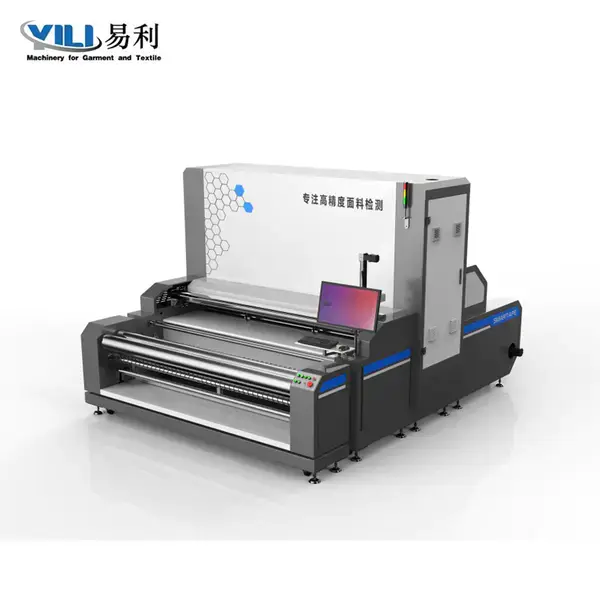

The textile industry is always on the lookout for innovative technologies that can streamline production processes and improve quality control. One such technology that is revolutionizing the way fabrics are inspected is the Intelligent Automatic Fabric Inspection Machine. This cutting-edge machine combines advanced artificial intelligence with state-of-the-art automation to provide accurate and efficient fabric inspection like never before.

The Intelligent Automatic Fabric Inspection Machine is equipped with a sophisticated computer vision system that can analyze the fabric in real-time. This system uses complex algorithms to detect and classify defects such as tears, holes, stains, and irregular patterns. By eliminating the need for manual inspection, this machine significantly reduces the chances of human error and ensures consistent and reliable results.

One of the key features of the Intelligent Automatic Fabric Inspection Machine is its ability to inspect fabrics at high speed. Traditional manual inspection methods are time-consuming and labor-intensive, often leading to bottlenecks in the production process. With this machine, fabrics can be inspected in a fraction of the time it would take a human inspector, allowing manufacturers to increase their production efficiency and meet tight deadlines.

In addition to speed and accuracy, the Intelligent Automatic Fabric Inspection Machine also offers a high level of functionality and flexibility. It can be programmed to inspect fabrics of varying sizes, shapes, colors, and textures, making it suitable for a wide range of textile products. The machine can also be customized to meet specific inspection requirements, ensuring that it can adapt to the unique needs of each manufacturer.

Furthermore, the Intelligent Automatic Fabric Inspection Machine is designed to be easy to use and maintain. Its user-friendly interface allows operators to set up and control the inspection process with minimal training. Additionally, the machine is equipped with self-diagnostic capabilities that can detect and report any issues, allowing for quick and timely maintenance.

Overall, the introduction of the Intelligent Automatic Fabric Inspection Machine represents a significant advancement in textile quality control. By combining intelligence and automation, this machine offers a level of efficiency, accuracy, and reliability that is unparalleled in the industry. With the ability to inspect fabrics quickly and precisely, manufacturers can improve their overall product quality and market competitiveness. As the textile industry continues to evolve, the Intelligent Automatic Fabric Inspection Machine is poised to become an essential tool for manufacturers looking to achieve excellence in quality control.

- How the Machine Revolutionizes Traditional Inspection Methods

In the fast-paced world of textile manufacturing, ensuring the quality of fabrics is of utmost importance. Traditionally, this has been done through manual inspection methods that are time-consuming, labor-intensive, and prone to human error. However, with the advent of intelligent automatic fabric inspection machines, the game has changed. These cutting-edge machines are revolutionizing traditional inspection methods and setting a new standard for quality control in the textile industry.

At the heart of these intelligent machines is their ability to automate the inspection process. By utilizing advanced technologies such as artificial intelligence, machine learning, and computer vision, these machines can identify and analyze defects in fabrics with incredible accuracy and efficiency. This not only speeds up the inspection process but also ensures a higher level of quality control.

One of the key features of intelligent automatic fabric inspection machines is their ability to detect a wide range of defects, from color variations and holes to weaving and printing errors. These machines can scan fabrics at high speeds, capturing detailed images of every inch of the material. The images are then analyzed in real-time, flagging any defects or irregularities that may affect the quality of the fabric.

Another advantage of these machines is their consistency. Unlike human inspectors who may get fatigued or lose focus over time, intelligent automatic fabric inspection machines are able to maintain a high level of accuracy and precision throughout the inspection process. This ensures that every fabric that passes through the machine meets the desired quality standards.

Furthermore, these machines are also highly customizable. Manufacturers can adjust the settings of the machine to suit their specific needs, whether it be the type of fabric being inspected, the type of defects being targeted, or the speed at which the inspection is conducted. This flexibility allows manufacturers to tailor the inspection process to their unique requirements, ultimately leading to a more efficient and effective quality control system.

In addition to improving the quality of fabrics, intelligent automatic fabric inspection machines also have the potential to reduce costs for manufacturers. By streamlining the inspection process and minimizing the need for manual labor, these machines can help companies save time and resources. This not only results in higher productivity but also in higher profitability for manufacturers in the long run.

Overall, the introduction of intelligent automatic fabric inspection machines is a game-changer for the textile industry. By revolutionizing traditional inspection methods and setting a new standard for quality control, these machines are paving the way for a more efficient, accurate, and cost-effective approach to fabric inspection. With their advanced technologies and impressive capabilities, intelligent automatic fabric inspection machines are poised to change the way textiles are inspected and ensure that only the highest quality fabrics make it to market.

- Benefits of Implementing the Machine in Textile Manufacturing

Textile manufacturing has long been a complex and labor-intensive process, with the quality control of fabrics being a crucial step in ensuring the end product meets the required standards. In recent years, however, significant advancements have been made in the field of fabric inspection with the introduction of the intelligent automatic fabric inspection machine.

This revolutionary technology has transformed the way textiles are inspected, offering a range of benefits that have greatly improved the efficiency and accuracy of quality control processes in the industry. From detecting defects to ensuring consistency in the production of fabrics, the intelligent automatic fabric inspection machine is a game-changer that is revolutionizing the textile manufacturing sector.

One of the key benefits of implementing the intelligent automatic fabric inspection machine is the significant increase in inspection speed and accuracy. Traditionally, fabric inspection has been a time-consuming and labor-intensive process that is prone to human error. With the introduction of this cutting-edge technology, manufacturers can now conduct inspections at a much faster pace, without compromising on the quality of the results. The machine's advanced algorithms and sensors are able to detect even the smallest defects in the fabric, ensuring that only products that meet the highest standards are passed on to the next stage of production.

In addition to speed and accuracy, the intelligent automatic fabric inspection machine also offers manufacturers greater consistency in their production processes. By eliminating the subjective nature of manual inspections, this technology ensures that all fabrics are inspected in a standardized and impartial manner. This not only helps to reduce the risk of defects slipping through the cracks but also enables manufacturers to maintain a uniform level of quality across their entire product range.

Furthermore, the intelligent automatic fabric inspection machine is also highly versatile and can be easily customized to meet the specific needs of different manufacturers. Whether it is detecting pattern defects, color variations, or weaving inconsistencies, this technology can be programmed to identify a wide range of issues that may arise during the manufacturing process. This level of flexibility allows manufacturers to address specific quality control challenges that may be unique to their production line, ultimately leading to improved overall product quality.

Overall, the introduction of the intelligent automatic fabric inspection machine has had a profound impact on the textile manufacturing industry. By streamlining the quality control process, improving inspection speed and accuracy, and ensuring greater consistency in production, this technology is helping manufacturers to produce textiles of the highest quality in a more efficient and cost-effective manner. As the industry continues to embrace advancements in technology, it is clear that the intelligent automatic fabric inspection machine is playing a vital role in shaping the future of textile manufacturing.

- Future Implications of Advancing Textile Quality Control Technology

Textile quality control has always been a critical aspect of the manufacturing process, ensuring that only the highest quality materials are used in the production of garments, home textiles, and other fabric-based products. With the introduction of the Intelligent Automatic Fabric Inspection Machine, the textile industry is on the brink of a revolution that promises to significantly improve the efficiency and accuracy of quality control processes.

The Intelligent Automatic Fabric Inspection Machine is a cutting-edge technology that uses artificial intelligence and machine learning algorithms to automatically detect and analyze defects in fabrics. This state-of-the-art machine is equipped with high-resolution cameras and sensors that can scan fabrics at a rapid pace, identifying even the smallest imperfections that may be missed by human operators. By utilizing advanced image processing techniques, the machine is able to distinguish between different types of defects, such as stains, holes, and tears, with a high degree of accuracy.

One of the key advantages of the Intelligent Automatic Fabric Inspection Machine is its ability to work quickly and efficiently, significantly reducing the time and labor required for quality control inspection. Traditional methods of fabric inspection typically involve manual examination by human operators, which can be time-consuming and prone to human error. With the introduction of this intelligent machine, manufacturers can now streamline their quality control processes, allowing them to inspect a larger volume of fabrics in a shorter amount of time.

In addition to improving efficiency, the Intelligent Automatic Fabric Inspection Machine also offers greater consistency and reliability in detecting defects. Human operators may vary in their ability to detect and classify defects accurately, leading to inconsistencies in the inspection process. By contrast, the machine’s automated system ensures that each fabric is rigorously inspected according to pre-defined quality standards, reducing the likelihood of errors and discrepancies in the inspection results.

Furthermore, the future implications of advancing textile quality control technology are vast and far-reaching. The integration of intelligent machines into the manufacturing process has the potential to revolutionize the way in which textiles are produced, enhancing product quality and consumer satisfaction. By implementing these cutting-edge technologies, manufacturers can improve their overall productivity, reduce waste, and minimize the risk of producing faulty products.

In conclusion, the introduction of the Intelligent Automatic Fabric Inspection Machine represents a significant milestone in the evolution of textile quality control technology. By leveraging the power of artificial intelligence and machine learning, this innovative technology has the potential to revolutionize the textile industry, improving efficiency, accuracy, and consistency in quality control processes. As manufacturers continue to embrace these advancements, the future of textile production looks brighter than ever before.

Conclusion

In conclusion, the introduction of the Intelligent Automatic Fabric Inspection Machine marks a significant advancement in the textile industry, revolutionizing the way quality control is conducted. This state-of-the-art technology not only improves efficiency and accuracy in fabric inspection processes, but also helps in reducing costs and maximizing productivity. With its intelligent features and automated capabilities, this machine is set to transform the way fabrics are inspected and ensure that only the highest quality products reach the market. As the textile industry continues to evolve and embrace technological innovations, the Intelligent Automatic Fabric Inspection Machine sets a new standard for excellence in quality control.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.