Revolutionizing Textile Production: Introducing The Automatic Edge Alignment Fabric Rolling Machine

Are you tired of spending hours struggling to perfectly align textile edges during the fabric rolling process? Look no further! In this groundbreaking article, we introduce the revolutionary Automatic Edge Alignment Fabric Rolling Machine, a game-changing innovation set to streamline and revolutionize textile production. Say goodbye to tedious manual labor and hello to a more efficient and precise way of working. Read on to discover how this cutting-edge technology is transforming the industry and making your production process easier than ever before.

- The Need for Innovation in Textile Production

Revolutionizing Textile Production: Introducing the Automatic Edge Alignment Fabric Rolling Machine

In the fast-paced world of textile production, efficiency is key. With the demand for textiles constantly on the rise, manufacturers are constantly seeking new ways to streamline their processes and increase output. One area that has long been in need of innovation is fabric rolling. The traditional method of manually rolling fabric is time-consuming and labor-intensive, leading to inefficiencies and errors in the production process. However, a new solution has emerged in the form of the Automatic Edge Alignment Fabric Rolling Machine.

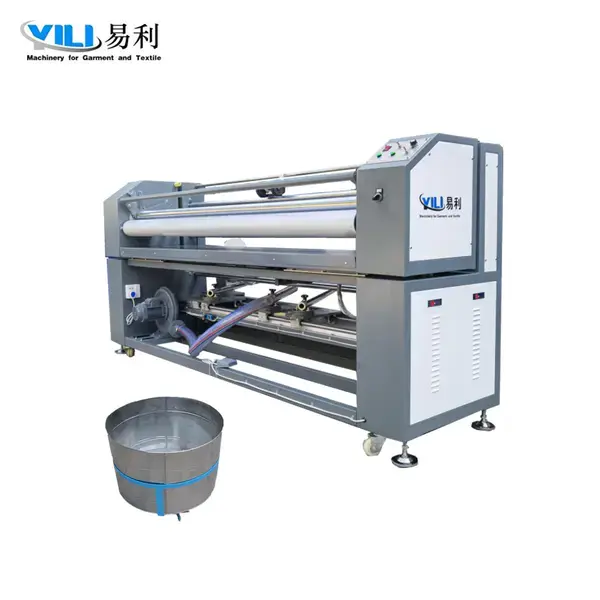

The Automatic Edge Alignment Fabric Rolling Machine is a game-changer in the world of textile production. This cutting-edge machine is equipped with advanced technology that allows it to automatically align the edges of the fabric as it is being rolled. This not only saves time and reduces the need for manual labor, but it also ensures that the fabric is rolled with precision and accuracy, leading to a higher quality end product.

One of the key features of the Automatic Edge Alignment Fabric Rolling Machine is its user-friendly interface. With just a few simple settings, operators can easily program the machine to roll fabric of various widths and lengths. This flexibility allows manufacturers to adapt to changing production needs quickly and efficiently, giving them a competitive edge in the market.

In addition to its efficiency and precision, the Automatic Edge Alignment Fabric Rolling Machine also offers other benefits to manufacturers. By reducing the need for manual labor, this machine helps to improve workplace safety and reduce the risk of injuries. It also helps to increase productivity and output, allowing manufacturers to meet deadlines and fulfill orders in a timely manner.

Furthermore, the Automatic Edge Alignment Fabric Rolling Machine is a sustainable solution for textile production. By optimizing the rolling process and reducing waste, this machine helps to minimize the environmental impact of manufacturing operations. This is crucial in today's world, where sustainability is becoming an increasingly important consideration for consumers and businesses alike.

Overall, the Automatic Edge Alignment Fabric Rolling Machine is a game-changing innovation in textile production. Its efficiency, precision, and sustainability make it a valuable asset for manufacturers looking to stay ahead in a competitive market. With this machine, the future of textile production looks bright, with faster turnaround times, higher quality products, and a more sustainable approach to manufacturing.

- The Automatic Edge Alignment Fabric Rolling Machine: Features and Functions

In today's fast-paced textile industry, efficiency and precision are key factors in ensuring a successful production process. The introduction of the Automatic Edge Alignment Fabric Rolling Machine has brought a new level of innovation to the manufacturing process, revolutionizing the way fabrics are handled and rolled.

The Automatic Edge Alignment Fabric Rolling Machine is a state-of-the-art piece of equipment designed to streamline the fabric rolling process. With its advanced features and functions, this machine is set to change the way textiles are produced, making the process more efficient and accurate than ever before.

One of the standout features of the Automatic Edge Alignment Fabric Rolling Machine is its automatic edge alignment technology. This innovative feature allows the machine to automatically detect and align the edges of the fabric as it is being rolled, ensuring that the fabric is rolled evenly and accurately every time. This eliminates the need for manual adjustments and reduces the risk of errors, resulting in a more consistent and high-quality final product.

The machine's automatic edge alignment technology is made possible by a series of sensors and actuators that work together to detect the edges of the fabric as it passes through the machine. These sensors send signals to the actuators, which then adjust the position of the fabric to ensure that it is aligned properly before it is rolled. This process happens in real-time, allowing the machine to make rapid adjustments as needed to maintain accurate edge alignment throughout the rolling process.

In addition to its automatic edge alignment technology, the Automatic Edge Alignment Fabric Rolling Machine also boasts a range of other features that make it a valuable asset in textile production. These include variable speed controls, programmable settings, and a user-friendly interface that allows operators to easily control and monitor the machine's performance.

The variable speed controls allow operators to adjust the speed of the machine to suit the requirements of different fabrics, while the programmable settings enable users to store and recall specific rolling configurations for different types of fabric. This versatility makes the machine adaptable to a wide range of production needs, making it a valuable investment for textile manufacturers looking to improve their efficiency and quality.

Overall, the Automatic Edge Alignment Fabric Rolling Machine is set to revolutionize the way textiles are produced, offering a level of efficiency and precision that was previously unimaginable. With its advanced features and functions, this machine is sure to become a staple in textile production facilities around the world, helping manufacturers to streamline their processes and deliver high-quality products to their customers.

- Improving Efficiency and Accuracy in Textile Manufacturing

In the fast-paced world of textile manufacturing, efficiency and accuracy are crucial factors in ensuring product quality and meeting consumer demand. Revolutionizing the traditional process of fabric rolling, the automatic edge alignment fabric rolling machine has emerged as a game-changer in the industry. By introducing automation and precision technology, this innovative machine is set to transform the way textiles are produced, offering numerous benefits to manufacturers.

The automatic edge alignment fabric rolling machine is designed to streamline the fabric rolling process, significantly reducing the time and labor required for this task. Traditionally, fabric rolling has been a manual process that is prone to errors and inconsistencies. With the automatic edge alignment machine, however, fabric can be rolled quickly and accurately, ensuring that each roll is uniform and perfectly aligned.

One of the key features of the automatic edge alignment fabric rolling machine is its advanced edge detection technology. This technology allows the machine to identify the edges of the fabric and adjust its alignment accordingly, ensuring that the fabric is rolled evenly and without any creases or wrinkles. This level of precision and accuracy can greatly improve the overall quality of the finished product, as well as reduce waste and rework.

Another advantage of the automatic edge alignment fabric rolling machine is its ability to increase production efficiency. By automating the fabric rolling process, manufacturers can significantly speed up production times and handle larger volumes of fabric with ease. This not only allows for faster turnaround times on orders but also enables manufacturers to meet tight deadlines and respond quickly to changing market demands.

Additionally, the automatic edge alignment fabric rolling machine can help reduce the risk of injuries and ergonomic strain for workers. Manual fabric rolling can be a physically demanding task, leading to fatigue and potential injuries for employees. By automating this process, manufacturers can create a safer and healthier work environment for their employees, ultimately improving overall productivity and morale.

Overall, the introduction of the automatic edge alignment fabric rolling machine marks a major step forward in textile manufacturing. With its ability to improve efficiency, accuracy, and worker safety, this innovative machine is set to revolutionize the way textiles are produced. As the industry continues to evolve and adapt to new technologies, the automatic edge alignment fabric rolling machine stands out as a beacon of progress and innovation.

- Revolutionizing the Industry with Automated Solutions

In an era where automation is disrupting traditional industries, the textile production sector is no exception. The introduction of the Automatic Edge Alignment Fabric Rolling Machine is set to transform the way fabrics are processed and rolled, offering a more efficient and precise solution for manufacturers worldwide. This innovative machine is revolutionizing the industry with its advanced automated features, making production processes faster, more accurate, and ultimately more cost-effective.

The key feature of the Automatic Edge Alignment Fabric Rolling Machine is its unique ability to align the edges of the fabric automatically during the rolling process. This technology eliminates the need for manual alignment, reducing the risk of human error and ensuring consistent quality in every roll of fabric. By streamlining this crucial step in the production process, manufacturers can increase their output and minimize waste, ultimately improving their bottom line.

One of the major advantages of the Automatic Edge Alignment Fabric Rolling Machine is its efficiency. Traditional fabric rolling processes are time-consuming and labor-intensive, requiring skilled workers to carefully align the edges of the fabric before rolling. With this automated machine, manufacturers can significantly reduce the time and labor required for this task, allowing them to focus on other aspects of production. This increased efficiency not only saves time and money but also allows manufacturers to meet tight deadlines and fulfill large orders with ease.

Another key benefit of the Automatic Edge Alignment Fabric Rolling Machine is its precision. Manual alignment of fabric edges can often result in uneven rolls, leading to inconsistencies in the final product. With its advanced technology, this automated machine ensures that fabric edges are perfectly aligned every time, resulting in high-quality rolls that meet the strictest industry standards. By eliminating human error from the equation, manufacturers can achieve greater consistency in their products, enhancing customer satisfaction and reputation.

Furthermore, the Automatic Edge Alignment Fabric Rolling Machine is versatile and adaptable to a wide range of fabrics. Whether working with delicate materials like silk or heavy-duty fabrics like denim, this machine can handle various types of fabrics with ease. Its adjustable settings and customizable features make it suitable for different production needs, allowing manufacturers to tailor the machine to their specific requirements.

In conclusion, the Automatic Edge Alignment Fabric Rolling Machine is a game-changer for the textile production industry. By revolutionizing the way fabrics are processed and rolled, this innovative machine offers manufacturers a more efficient, accurate, and cost-effective solution. With its advanced automated features, the machine is set to transform production processes, setting a new standard for quality and efficiency in the industry. As automation continues to shape the future of manufacturing, the Automatic Edge Alignment Fabric Rolling Machine is leading the way towards a more streamlined and sustainable textile production sector.

- Future Prospects and Possibilities in Textile Production

The textile industry has seen numerous advancements in recent years, with the introduction of cutting-edge technology transforming the way fabrics are produced and processed. One such innovation that is revolutionizing textile production is the Automatic Edge Alignment Fabric Rolling Machine. This state-of-the-art machine offers promising future prospects and possibilities in the realm of textile manufacturing.

The Automatic Edge Alignment Fabric Rolling Machine is a game-changer in the industry, providing a faster, more efficient, and more precise method of rolling fabrics. Traditional fabric rolling processes often require manual labor and are prone to errors and inconsistencies. With the introduction of this automated machine, manufacturers can now achieve perfectly aligned fabric rolls with minimal human intervention, saving both time and resources.

One of the key features of the Automatic Edge Alignment Fabric Rolling Machine is its advanced edge alignment technology. This cutting-edge system ensures that the fabric is rolled with utmost precision, eliminating any irregularities or distortions in the process. This not only improves the overall quality of the fabric rolls but also reduces wastage and enhances productivity.

Furthermore, the Automatic Edge Alignment Fabric Rolling Machine is equipped with intelligent sensors and software that enable it to detect and correct any deviations in the alignment of the fabric. This ensures that each fabric roll is consistent in terms of width and alignment, meeting the highest standards of quality control.

In addition to its precise edge alignment capabilities, the Automatic Edge Alignment Fabric Rolling Machine also offers a range of other advantages. It can handle a wide variety of fabrics, from delicate silk to heavy-duty denim, making it a versatile and adaptable solution for textile manufacturers. Its high-speed operation allows for quicker turnaround times and increased production output, giving businesses a competitive edge in the market.

Moreover, the Automatic Edge Alignment Fabric Rolling Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and controls require minimal training, allowing operators to quickly familiarize themselves with the machine and start using it efficiently. This not only streamlines the production process but also reduces the risk of errors and downtime.

Overall, the introduction of the Automatic Edge Alignment Fabric Rolling Machine signifies a new era in textile production, with endless possibilities and prospects for the industry. As manufacturers continue to embrace this cutting-edge technology, they can expect improved efficiency, enhanced quality, and increased profitability in their operations. With its advanced capabilities and innovative design, this automated machine is set to transform the way fabrics are rolled and pave the way for a brighter future in textile manufacturing.

Conclusion

In conclusion, the introduction of the Automatic Edge Alignment Fabric Rolling Machine is truly revolutionizing the textile production industry. With its innovative technology and precision in edge alignment, this machine has the potential to streamline the fabric rolling process and increase efficiency in production. By reducing the time and labor required for this task, textile manufacturers can now focus on other aspects of their production process, leading to increased productivity and profitability. With the Automatic Edge Alignment Fabric Rolling Machine, the future of textile production is looking brighter than ever.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.