Revolutionizing Quality Control: The Ultimate Denim Fabric Inspection Machine

Are you tired of labor-intensive denim fabric inspection processes? Look no further. Our revolutionary denim fabric inspection machine is set to transform the way quality control is done in the textile industry. With cutting-edge technology and unmatched precision, this machine ensures the highest quality standards are met with utmost efficiency. Dive into this article to discover how this ultimate denim fabric inspection machine is changing the game in the world of textile production.

- Introduction to the Ultimate Denim Fabric Inspection Machine

The denim industry has long been searching for a revolutionary solution to improve the quality control process in fabric inspection. This search has culminated in the creation of the Ultimate Denim Fabric Inspection Machine - a cutting-edge technology designed to revolutionize the way denim fabric is inspected.

Denim fabric is known for its durability, versatility, and timeless appeal. However, in order to maintain its high quality standards, it is crucial for manufacturers to ensure that each roll of denim fabric meets certain criteria. This is where the denim fabric inspection machine comes into play.

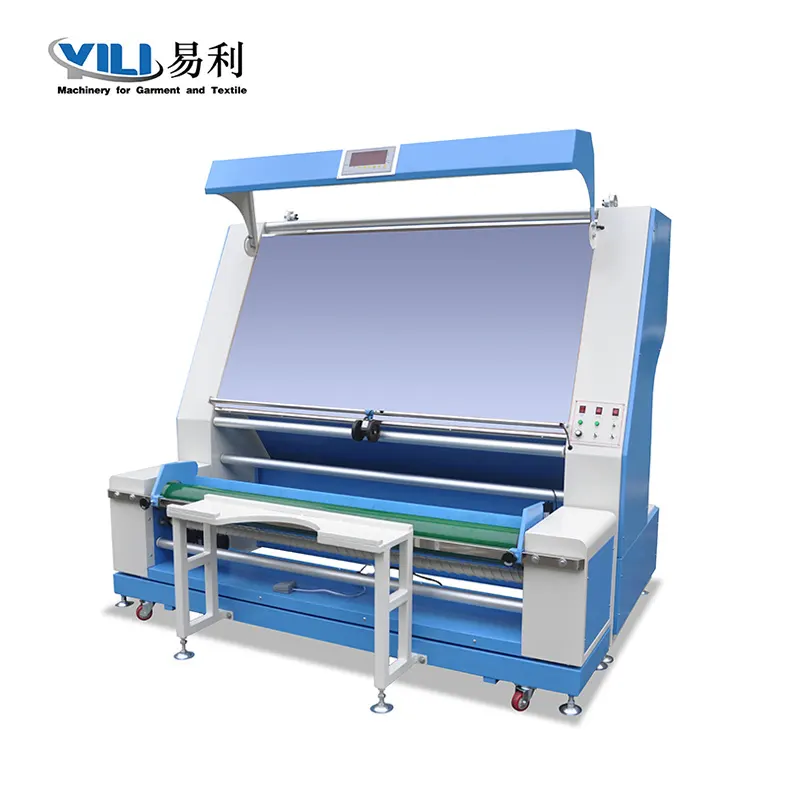

The Ultimate Denim Fabric Inspection Machine is unlike any other machine on the market. It is equipped with state-of-the-art sensors and imaging technology that allow it to detect even the smallest imperfections in the fabric. Whether it's a tiny tear, a loose thread, or a color inconsistency, this machine can identify and flag any issues in real-time.

One of the key features of the denim fabric inspection machine is its speed and efficiency. Traditional methods of fabric inspection are time-consuming and labor-intensive, often requiring multiple inspectors to manually check each roll of fabric. With the Ultimate Denim Fabric Inspection Machine, this process is streamlined and automated, allowing manufacturers to inspect large quantities of fabric in a fraction of the time.

In addition to its speed and accuracy, the denim fabric inspection machine also offers a level of consistency that is unmatched by human inspectors. By using predetermined criteria and algorithms, the machine can ensure that each roll of fabric is inspected in the same thorough and systematic manner, eliminating the risk of human error.

Furthermore, the denim fabric inspection machine is designed to be user-friendly and easy to operate. With a user-friendly interface and intuitive controls, manufacturers can quickly set up the machine and begin inspecting fabric with minimal training. This makes it an ideal solution for denim manufacturers of all sizes, from small boutique shops to large-scale production facilities.

Overall, the Ultimate Denim Fabric Inspection Machine represents a significant advancement in the field of quality control for denim fabric. By combining cutting-edge technology with speed, accuracy, and ease of use, this machine has the potential to revolutionize the way denim is inspected and ensure that only the highest quality fabric makes its way to consumers. With the introduction of this groundbreaking technology, the denim industry is poised to enter a new era of quality control and production efficiency.

- How the Machine is Changing the Game in Quality Control for Denim Fabric

In recent years, the denim industry has undergone a significant transformation with the introduction of advanced technology in quality control processes. One of the most groundbreaking innovations in this field is the denim fabric inspection machine, a cutting-edge piece of equipment that is revolutionizing the way denim fabric is inspected for defects and inconsistencies.

Traditionally, quality control in the denim industry has been a labor-intensive and time-consuming process, involving human inspectors meticulously examining each meter of fabric for flaws such as weaving defects, dye irregularities, and sizing issues. This manual inspection process is not only prone to human error but also limited in its ability to detect subtle defects that may go unnoticed by the naked eye.

Enter the denim fabric inspection machine – a game-changer in the world of quality control. This state-of-the-art machine is equipped with a range of advanced sensors and imaging technology that allow it to scan denim fabric with unparalleled precision and accuracy. By utilizing artificial intelligence and machine learning algorithms, the machine is able to quickly analyze the data obtained from the scans and identify even the smallest defects with remarkable efficiency.

One of the key features of the denim fabric inspection machine is its ability to detect defects in real-time as the fabric moves through the machine. This means that manufacturers can identify and address issues immediately, preventing defective fabric from being used in the production process and ultimately saving time and money in the long run.

Another advantage of the denim fabric inspection machine is its ability to generate detailed reports and analytics on the quality of the fabric being inspected. These insights allow manufacturers to gain a deeper understanding of the root causes of defects and make informed decisions on process improvements and optimizations.

Furthermore, the denim fabric inspection machine is also environmentally friendly, as it significantly reduces the amount of waste produced during the quality control process. By minimizing the need for manual inspection and rework, the machine helps to conserve resources and reduce the carbon footprint of denim production.

Overall, the denim fabric inspection machine is a game-changer in the world of quality control for denim fabric. Its advanced technology, real-time defect detection, and environmental benefits make it an indispensable tool for manufacturers looking to improve the quality and efficiency of their production processes. As the denim industry continues to evolve, the role of the denim fabric inspection machine will only become more vital in ensuring that denim products meet the highest standards of quality and performance.

- Features and Benefits of the Revolutionary Denim Fabric Inspection Machine

Revolutionizing Quality Control: The Ultimate Denim Fabric Inspection Machine - Features and Benefits of the Revolutionary Denim Fabric Inspection Machine

Denim fabric is a staple in the fashion industry, with its durable and versatile nature making it a favorite for clothing manufacturers worldwide. However, the production of denim fabric involves numerous intricate processes that can impact its quality. From weaving and dyeing to finishing and cutting, any defects in the fabric can lead to costly rejections and rework.

To address these challenges, the denim industry has been revolutionized by the introduction of the ultimate denim fabric inspection machine. This cutting-edge technology combines advanced automation and artificial intelligence to provide unparalleled efficiency and accuracy in quality control. In this article, we will explore the features and benefits of this revolutionary machine and how it is transforming the way denim fabric is inspected.

One of the key features of the denim fabric inspection machine is its high-speed scanning capability. Equipped with state-of-the-art sensors and cameras, the machine can examine the entire length and width of the fabric in a fraction of the time it would take a human inspector. This not only improves efficiency but also ensures a more thorough inspection, catching even the smallest defects that might be missed by the naked eye.

Another standout feature of the denim fabric inspection machine is its intelligent defect detection system. Using machine learning algorithms, the machine can automatically identify and classify different types of defects, such as holes, tears, stains, or uneven dyeing. This not only speeds up the inspection process but also reduces the chances of human error and inconsistency in defect detection.

Furthermore, the denim fabric inspection machine is equipped with an intuitive user interface that allows operators to easily customize inspection parameters and settings. This flexibility enables manufacturers to adapt the machine to different fabric types, production lines, and quality standards, ensuring consistent and reliable results every time.

In addition to its advanced features, the denim fabric inspection machine offers a range of benefits to manufacturers. By automating the inspection process, the machine helps to reduce labor costs and improve overall production efficiency. It also minimizes the risk of human error and subjectivity, leading to more accurate and reliable inspection results.

Moreover, the machine can help to increase the quality of denim fabric by identifying defects early in the production process. This not only reduces the number of fabric rejects and reworks but also enhances customer satisfaction by delivering products of the highest quality standards.

In conclusion, the ultimate denim fabric inspection machine is revolutionizing the way denim fabric is inspected, offering unmatched efficiency, accuracy, and flexibility in quality control. By leveraging advanced automation and artificial intelligence, this cutting-edge technology is helping manufacturers to improve production processes, reduce costs, and deliver superior quality denim fabric to the market. With its innovative features and benefits, the denim fabric inspection machine is truly a game-changer in the denim industry.

- The Impact of the Machine on the Textile Industry

The textile industry has been revolutionized by the introduction of the denim fabric inspection machine. This cutting-edge technology has had a significant impact on the quality control processes within the industry, leading to more efficient and precise inspections of denim fabrics.

One of the key features of the denim fabric inspection machine is its ability to detect flaws and defects in the fabric with incredible accuracy. By utilizing advanced imaging technology, the machine is able to quickly scan and analyze the fabric for any imperfections, such as holes, stains, or uneven dyeing. This ensures that only high-quality denim fabrics are delivered to customers, leading to increased customer satisfaction and reduced returns.

Furthermore, the denim fabric inspection machine has greatly streamlined the inspection process, saving both time and labor costs for textile manufacturers. In the past, manual inspections were time-consuming and often prone to human error. With the introduction of the machine, inspections can now be completed in a fraction of the time, allowing manufacturers to increase their production output and meet tight deadlines more efficiently.

Another major advantage of the denim fabric inspection machine is its ability to provide detailed reports and data analysis on the fabric quality. By collecting and analyzing data on fabric defects, manufacturers can identify trends and patterns that may be indicative of larger issues in the production process. This allows for quick adjustments to be made to improve overall quality and prevent defects from occurring in the future.

Overall, the denim fabric inspection machine has had a profound impact on the textile industry, revolutionizing the way in which quality control is conducted. With its advanced imaging technology, streamlined inspection process, and detailed data analysis capabilities, the machine has helped manufacturers to produce high-quality denim fabrics more efficiently and effectively than ever before. As the industry continues to evolve, the denim fabric inspection machine will undoubtedly play a crucial role in ensuring the continued success and growth of textile manufacturers worldwide.

- Looking Towards the Future: Innovations in Quality Control for Denim Fabric

Denim has been a staple in fashion for decades, loved for its durability, versatility, and timeless appeal. However, producing high-quality denim fabric is no easy feat, as it requires meticulous attention to detail and rigorous quality control measures. In recent years, advancements in technology have revolutionized the way denim fabric is inspected, leading to the development of the ultimate denim fabric inspection machine.

This groundbreaking innovation is set to change the game for denim manufacturers worldwide, as it promises to streamline the inspection process, improve accuracy, and ultimately enhance the quality of denim fabric. By looking towards the future and embracing these innovations in quality control, denim manufacturers can stay ahead of the curve and meet the increasingly high standards of today's discerning consumers.

One of the key features of the denim fabric inspection machine is its advanced imaging technology, which allows for detailed and precise analysis of the fabric. By capturing high-resolution images of the denim, the machine can detect even the smallest imperfections, such as color inconsistencies, weaving defects, or stray threads. This level of thorough inspection ensures that only the highest quality denim fabric makes it to the market, eliminating the risk of subpar products reaching consumers.

Moreover, the denim fabric inspection machine is equipped with cutting-edge automation capabilities, which significantly speed up the inspection process. Traditionally, denim inspection was a labor-intensive and time-consuming task, requiring skilled workers to examine each yard of fabric manually. With the new machine, this process is streamlined and expedited, allowing manufacturers to inspect larger quantities of fabric in a fraction of the time.

In addition to improving efficiency, the denim fabric inspection machine also enhances the accuracy of quality control. Human error is a common factor in manual inspection processes, as fatigue or oversight can lead to missed defects. By automating the inspection process, manufacturers can minimize the risk of errors and ensure that every inch of denim fabric meets their exacting standards.

Furthermore, the denim fabric inspection machine is customizable to suit the specific needs of each manufacturer. Whether it's adjusting the sensitivity of the imaging technology or fine-tuning the inspection criteria, the machine can be tailored to meet the unique requirements of different denim producers. This level of customization ensures that manufacturers can maintain consistency in their quality control measures and deliver a superior product to their customers.

Overall, the ultimate denim fabric inspection machine represents a significant leap forward in the world of denim manufacturing. By harnessing the power of technology and innovation, manufacturers can achieve unparalleled levels of quality control, ensuring that their denim fabric meets the highest standards of excellence. As the industry continues to evolve and demand for premium denim grows, investing in these cutting-edge inspection machines is not just a choice, but a necessity for staying competitive in the market.

Conclusion

In conclusion, the development of the Ultimate Denim Fabric Inspection Machine represents a significant advancement in quality control for the denim industry. By revolutionizing the way denim fabric is inspected, this machine has the potential to greatly improve efficiency and accuracy in the production process. With its innovative features and cutting-edge technology, it is clear that this machine is poised to set a new standard in the industry. As manufacturers continue to prioritize quality control and strive for excellence in their products, the Ultimate Denim Fabric Inspection Machine will undoubtedly play a crucial role in helping them achieve their goals. Its impact on the industry is bound to be far-reaching, and we can expect to see a new era of superior denim products thanks to this groundbreaking technology.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.