Maximizing Safety And Efficiency: The Advantages Of A Double Head Needle Detector

Are you looking to enhance safety and efficiency in your workplace? Look no further than the double head needle detector. In this article, we explore the numerous advantages of this cutting-edge technology and how it can revolutionize your operations. Join us as we delve into the world of needle detection and discover the benefits of investing in this essential equipment.

- Introduction to double head needle detectors

Whether you work in a manufacturing facility, a food processing plant, or a textile factory, safety and efficiency are paramount in ensuring the smooth operation of your business. One crucial piece of equipment that can help maximize both safety and efficiency is the double head needle detector. In this article, we will explore the advantages of using a double head needle detector and how it can greatly benefit your business.

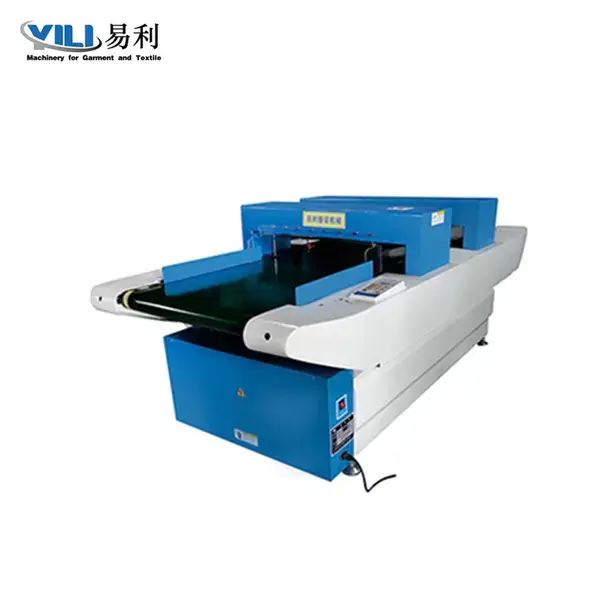

First and foremost, let's delve into what a double head needle detector is and how it works. A double head needle detector is a specialized piece of equipment that is used to detect any metallic contaminants, such as needles or broken pieces of metal, in products before they are packaged and shipped out. This is especially important in industries like food processing, where even the smallest metal contaminant can pose a serious health risk to consumers.

The double head needle detector, as the name suggests, is equipped with two detection heads, which allows for a more thorough inspection of products as they pass through the detector. This dual-head setup ensures that any metal contaminants, regardless of their size or shape, are detected and removed before the product reaches the consumer.

One of the key advantages of using a double head needle detector is its increased sensitivity and accuracy. The dual-head configuration allows for a higher level of precision in detecting metal contaminants, reducing the risk of false alarms and unnecessary product recalls. This not only saves time and money for your business but also helps maintain the trust and loyalty of your customers.

Furthermore, the double head needle detector is designed for ease of use and minimal maintenance. With advanced technology and user-friendly controls, operators can quickly set up and calibrate the detector for different products, ensuring consistent and reliable performance. Additionally, the durable construction of the detector means that it can withstand the rigors of daily use in a busy production environment, providing long-lasting reliability and peace of mind.

In conclusion, the advantages of using a double head needle detector in your business are clear. By maximizing safety and efficiency, you can protect your customers, your brand reputation, and your bottom line. Investing in a double head needle detector is not only a smart business decision but also a testament to your commitment to quality and excellence. So why wait? Upgrade your safety measures today with a double head needle detector and reap the benefits for years to come.

- How double head needle detectors improve safety in the workplace

In today's fast-paced and high-pressure work environments, ensuring the safety of employees is paramount. One crucial tool in maintaining workplace safety is the double head needle detector. This sophisticated piece of equipment plays a vital role in detecting and preventing potential hazards, such as needle contamination, in various industries.

The double head needle detector is a cutting-edge device designed to scan materials, products, and packages for the presence of foreign objects, particularly needles. With its advanced technology and high sensitivity levels, this detection system can effectively pinpoint the exact location of any metal contaminants, ensuring that they are promptly removed before they pose a threat to employees.

One of the key advantages of using a double head needle detector is its ability to improve workplace safety. By swiftly identifying and removing needles or other metal objects, this device helps prevent serious injuries, such as puncture wounds or infections, which can have long-lasting consequences for employees and businesses alike. In industries where needle contamination is a potential risk, such as food processing, textiles, and medical facilities, the use of a double head needle detector is essential in maintaining a safe working environment.

Furthermore, the efficiency of a double head needle detector also contributes to overall productivity in the workplace. By quickly and accurately detecting metal contaminants, this equipment minimizes downtime caused by product recalls, quality control issues, and safety incidents. This not only saves time and resources but also safeguards a company's reputation and customer trust.

Additionally, the double head needle detector is user-friendly and easy to operate, making it a practical solution for businesses of all sizes. With its intuitive interface and customizable settings, employees can quickly learn how to use this device effectively, without the need for extensive training or specialized skills. This accessibility ensures that companies can easily implement and integrate the double head needle detector into their existing safety protocols, enhancing overall workplace safety without significant disruptions.

In conclusion, the advantages of a double head needle detector are invaluable in today's fast-paced and demanding work environments. By improving workplace safety, increasing efficiency, and promoting user-friendly operation, this cutting-edge detection system is a must-have tool for businesses seeking to protect their employees and maintain high standards of quality. Investing in a double head needle detector is not just a proactive measure for preventing workplace hazards, but also a strategic decision that can have a lasting impact on a company's success and reputation.

- The efficiency benefits of using a double head needle detector

Needle detection technology has become an essential component in the manufacturing industry, particularly in industries where sewing and textile work is prevalent. The use of needle detectors has significantly improved safety protocols and efficiency in factories, ensuring that products are free from any metal contaminants that may pose a risk to consumers. In recent years, the double head needle detector has emerged as a game-changer in this technology, offering unparalleled benefits in terms of efficiency, accuracy, and ease of use.

One of the key advantages of using a double head needle detector is its high level of sensitivity and precision in detecting even the smallest metal particles. This ensures that products are thoroughly inspected for any potential hazards before they leave the manufacturing facility. The dual-head design of the detector allows for a more thorough scan of the product, reducing the chances of false positives and ensuring that no contaminated items slip through undetected.

In addition to its superior detection capabilities, the double head needle detector also offers significant efficiency benefits. By having two detection heads working simultaneously, the detector can scan a wider area of the product at a faster pace, reducing the time and labor required for inspection. This not only speeds up the production process but also minimizes the risk of human error, ensuring consistent and reliable results.

Furthermore, the double head needle detector is designed with user-friendliness in mind, with intuitive controls and easy-to-read displays that make operation simple and straightforward. This allows operators to quickly and effectively scan products without the need for extensive training or specialized skills. The detector also features advanced settings and customization options, allowing manufacturers to tailor the detection sensitivity to their specific needs and requirements.

Overall, the benefits of using a double head needle detector are undeniable. Not only does it enhance safety and quality control in the manufacturing process, but it also improves efficiency and productivity. By investing in this advanced technology, manufacturers can ensure that their products meet the highest standards of safety and quality, gaining the trust and loyalty of their customers.

In conclusion, the double head needle detector is a must-have tool for any manufacturer looking to maximize safety and efficiency in their production process. Its superior detection capabilities, efficiency benefits, and user-friendly design make it an invaluable asset in the fight against metal contamination. By incorporating this advanced technology into their operations, manufacturers can ensure the integrity of their products and the satisfaction of their customers.

- Comparing single head and double head needle detectors

In today's fast-paced and high-demand manufacturing industry, the importance of maximizing safety and efficiency cannot be understated. This is why more and more companies are turning to advanced technology such as the double head needle detector to ensure their products meet the highest standards of quality and safety.

Needle detectors are an essential tool in the manufacturing process, especially in industries such as food production, textiles, and pharmaceuticals where the presence of foreign objects such as needles can have serious consequences. Traditional single head needle detectors have long been used to detect these contaminants, but with advancements in technology, the double head needle detector has emerged as a superior solution.

One of the key advantages of a double head needle detector is its ability to detect contaminants from multiple angles. Unlike single head detectors that can only detect objects passing directly under the sensor, double head detectors are equipped with two sensors positioned at different angles. This allows for a more thorough and accurate detection process, reducing the risk of missing any contaminants that may be present in the product.

In addition to their increased detection capabilities, double head needle detectors also offer improved efficiency. With two sensors working simultaneously, these detectors are able to scan products at a faster rate, leading to higher throughput and reduced processing time. This not only improves productivity but also minimizes the risk of contaminated products reaching the market, ultimately saving companies time and money in potential recalls and loss of reputation.

Furthermore, double head needle detectors are also more versatile in terms of the types of products they can inspect. Whether it be large or irregularly shaped products, double head detectors are able to effectively scan a wide range of items with different sizes and shapes. This versatility is crucial for industries that produce a variety of products and need a reliable and consistent method of detecting contaminants.

Another advantage of double head needle detectors is their ease of use and maintenance. With two sensors working in tandem, these detectors are designed to be user-friendly and require minimal training to operate. Additionally, maintenance is simplified as the dual sensors are less prone to wear and tear compared to single head detectors, reducing the need for frequent repairs and replacements.

Overall, the advantages of a double head needle detector are clear. From improved detection capabilities and efficiency to versatility and ease of use, these advanced detectors offer a comprehensive solution for companies looking to maximize safety and efficiency in their manufacturing processes. As technology continues to evolve, it is clear that double head needle detectors will play a pivotal role in ensuring the highest standards of quality and safety in a wide range of industries.

- Strategies for maximizing the benefits of a double head needle detector

In today's fast-paced world, safety and efficiency in manufacturing are paramount. Companies are constantly seeking ways to enhance their production processes while also ensuring the safety of their products and customers. One innovative solution that has been gaining popularity in recent years is the double head needle detector. This advanced technology offers a multitude of benefits for companies looking to maximize safety and efficiency in their operations.

A double head needle detector is a high-tech piece of equipment designed to detect any foreign objects, such as needles or metal fragments, in products passing through a production line. By utilizing two detection heads, this machine can provide even greater accuracy and sensitivity than traditional single head detectors. This means that companies can have added peace of mind knowing that their products are free from potential contaminants that could harm consumers.

One of the key advantages of a double head needle detector is its ability to minimize false alarms. With two detection heads working simultaneously, the chances of a false alarm are significantly reduced. This not only saves time and resources but also helps to streamline the production process by eliminating unnecessary interruptions. Additionally, the dual-head design allows for faster processing speeds, further enhancing efficiency in the manufacturing process.

Another benefit of a double head needle detector is its versatility. This equipment can be easily integrated into existing production lines, making it a cost-effective solution for companies looking to enhance their safety measures. Whether it's in the food, pharmaceutical, or textile industry, a double head needle detector can provide peace of mind for companies and consumers alike.

To maximize the benefits of a double head needle detector, companies should implement a few key strategies. First and foremost, regular maintenance and calibration of the equipment are essential to ensure optimal performance. This includes checking for any wear and tear on the detection heads, as well as calibrating the sensitivity settings to match the specific needs of the production line.

Additionally, proper training for employees operating the double head needle detector is crucial. By providing comprehensive training on how to use the equipment effectively, companies can minimize the risk of human error and ensure that the detector is being utilized to its full potential. This can help to further enhance the safety and efficiency of the manufacturing process.

In conclusion, the advantages of a double head needle detector are clear. From increased accuracy and sensitivity to reduced false alarms and enhanced efficiency, this technology offers a wide range of benefits for companies looking to prioritize safety in their production processes. By implementing strategies for maximizing the benefits of a double head needle detector, companies can enhance their safety measures and streamline their operations, ultimately leading to a more successful and sustainable business.

Conclusion

In conclusion, the advantages of using a double head needle detector cannot be understated when it comes to maximizing safety and efficiency in various industries. With its ability to detect even the smallest metal contaminants and its dual head feature for increased accuracy, the double head needle detector proves to be a valuable tool for ensuring product quality and preventing potential hazards. By investing in this advanced technology, businesses can streamline their production processes, protect their customers, and ultimately enhance their reputation in the market. Overall, the benefits of utilizing a double head needle detector far outweigh the initial cost, making it a wise investment for any organization looking to prioritize safety and efficiency in their operations.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.