Ensuring Safety: The Importance Of Single Head Needle Detectors

In today's fast-paced world, safety is of utmost importance in every industry. One crucial tool in ensuring the safety of individuals is the single head needle detector. In this article, we will delve into the importance of these detectors and how they play a vital role in safeguarding both employees and consumers. Join us as we explore the significance of single head needle detectors in maintaining a secure environment.

Understanding the significance of single head needle detectors

In today's fast-paced world, ensuring safety in various industries and settings is crucial. One important tool in maintaining safety is the single head needle detector, which plays a significant role in preventing accidents and injuries. This article will delve into the importance of single head needle detectors and their impact on safety measures.

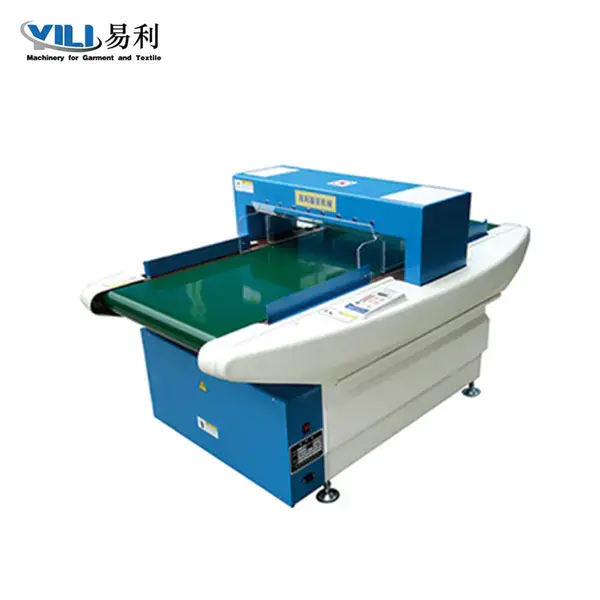

Single head needle detectors are essential devices used to detect metallic contaminants in various products, such as clothing, food, and pharmaceuticals. These detectors operate by emitting electromagnetic fields and identifying any metal objects that pass through them. By detecting small metal fragments or needles in products, single head needle detectors help prevent potential harm to consumers and ensure product quality and safety.

One of the key reasons why single head needle detectors are so crucial is their role in preventing serious injuries and accidents. In industries such as food processing and garment manufacturing, the presence of metal contaminants in products can lead to severe consequences for consumers. For example, ingesting metal shards in food products can result in internal injuries and pose a significant health risk. By using single head needle detectors, manufacturers can identify and remove any metal contaminants before products reach consumers, thus reducing the likelihood of accidents and injuries.

Moreover, single head needle detectors play a vital role in maintaining compliance with industry regulations and standards. In industries where product safety is of paramount importance, such as the food and pharmaceutical sectors, strict guidelines are in place to ensure the quality and integrity of products. Single head needle detectors help companies adhere to these regulations by effectively detecting and eliminating metal contaminants. By investing in these detectors, businesses can demonstrate their commitment to upholding safety standards and protecting consumer health.

In addition to preventing accidents and ensuring compliance, single head needle detectors also offer cost-effective solutions for businesses. By incorporating these detectors into their manufacturing processes, companies can avoid costly product recalls and protect their reputation from potential harm. Detecting metal contaminants early on can save businesses from facing legal liabilities and financial losses associated with product recalls. As such, single head needle detectors not only contribute to safety but also offer long-term benefits for businesses in terms of efficiency and cost-effectiveness.

Furthermore, the importance of single head needle detectors extends beyond safety considerations to encompass broader implications for consumer trust and confidence. When consumers purchase products, they trust that these items have undergone rigorous quality control measures to ensure their safety. By incorporating single head needle detectors into their production processes, companies can instill confidence in consumers and build a positive reputation for their brands. Ensuring product safety through the use of these detectors is a testament to a company's commitment to quality and consumer wellbeing.

In conclusion, single head needle detectors play a crucial role in ensuring safety and quality in various industries. These devices not only help prevent accidents and injuries but also support compliance with industry regulations and standards. By investing in single head needle detectors, businesses can protect consumer health, uphold safety standards, and enhance their reputation. In an increasingly competitive marketplace, the significance of these detectors cannot be overstated, as they serve as essential tools in safeguarding consumer trust and preserving brand integrity.

How single head needle detectors enhance workplace safety

In today's fast-paced workplace environment, safety is a top priority for employers and employees alike. With the rise in workplace injuries caused by sharp objects such as needles, single head needle detectors have become an essential tool in enhancing workplace safety.

Single head needle detectors are advanced devices designed to detect and alert users of the presence of any sharp objects, such as needles, within a specific area. These detectors are commonly used in industries such as healthcare, manufacturing, and hospitality, where employees are at a higher risk of encountering needles or other hazardous objects.

One of the key benefits of single head needle detectors is their ability to quickly and accurately detect sharp objects, helping to prevent accidental injuries and exposure to harmful substances. By using advanced technology such as metal detection sensors and alarm systems, these detectors can alert users of the presence of needles within seconds, allowing for immediate action to be taken.

Furthermore, single head needle detectors are easy to use and maintain, making them a cost-effective solution for businesses looking to enhance workplace safety. With simple installation and calibration processes, these detectors can be easily integrated into existing safety protocols, providing an added layer of protection for employees and customers alike.

In addition to enhancing workplace safety, single head needle detectors also play a crucial role in preventing the spread of infectious diseases. In healthcare settings, where needles are frequently used, the risk of needlestick injuries can lead to serious health implications for both patients and healthcare providers. By implementing single head needle detectors, healthcare facilities can minimize the risk of needlestick injuries and reduce the spread of infectious diseases, ultimately creating a safer environment for all.

Overall, the importance of single head needle detectors in ensuring workplace safety cannot be overstated. From preventing accidents and injuries to reducing the spread of infectious diseases, these advanced devices play a vital role in protecting employees and customers in a variety of industries. As workplace safety continues to be a top priority, single head needle detectors will undoubtedly remain a key tool in creating a safe and secure environment for all.

Features and benefits of using single head needle detectors

Single head needle detectors are crucial tools in ensuring safety in various industries, particularly in the food and textile sectors where needles and other metal contaminants can pose serious health risks to consumers. These detectors offer a range of features and benefits that make them an indispensable component of quality control and safety protocols.

One of the key features of single head needle detectors is their ability to accurately and efficiently detect metal contaminants in products. These detectors use advanced technology to scan products for any metal objects, including needles, staples, or fragments, ensuring that only safe and contaminant-free products are allowed to pass through the production line. This level of precision is essential in preventing potentially harmful objects from reaching consumers and avoiding costly recalls or damage to a company's reputation.

Another advantage of using single head needle detectors is their ease of use and versatility. These detectors can be easily integrated into existing production lines, requiring minimal maintenance and calibration. They can be adjusted to accommodate different product sizes and materials, making them suitable for a wide range of applications. Additionally, single head needle detectors are typically designed to be user-friendly, with intuitive controls and functions that allow operators to quickly and efficiently scan products for contaminants.

In addition to their detection capabilities, single head needle detectors also offer benefits in terms of efficiency and cost-effectiveness. By identifying contaminants early in the production process, these detectors help minimize waste and rework, as contaminated products can be promptly removed from the line. This not only reduces the risk of product recalls but also saves time and resources for manufacturers. Investing in a single head needle detector can ultimately lead to cost savings by preventing product contamination and ensuring compliance with industry standards and regulations.

Furthermore, single head needle detectors play a crucial role in ensuring product quality and consumer safety. By detecting and removing metal contaminants from products, these detectors help uphold the integrity of brands and products, giving consumers confidence in the safety and reliability of the items they purchase. This is particularly important in industries like food and textiles, where even small metal fragments can pose serious health risks if ingested or come into contact with skin.

Overall, the features and benefits of using single head needle detectors make them essential tools for safeguarding consumer health and protecting brands from potential contamination incidents. With their precision, efficiency, and cost-effectiveness, these detectors offer a dependable line of defense against metal contaminants, helping companies maintain high standards of quality and safety in their products. Investing in a single head needle detector is not only a smart business decision but also a critical step in ensuring the well-being of consumers and upholding a company's reputation in the marketplace.

Proper usage and maintenance of single head needle detectors

Single head needle detectors are an essential tool in various industries to ensure the safety and well-being of users and consumers. These detectors play a crucial role in detecting any sharp objects, such as needles, pins, or blades, that may be inadvertently present in products or materials. Proper usage and maintenance of single head needle detectors are paramount in guaranteeing their effectiveness and reliability in detecting foreign objects.

To ensure the optimal performance of single head needle detectors, it is essential to follow the manufacturer's guidelines for their usage. This includes understanding the operating instructions, calibration procedures, and safety precautions. Users should be trained on how to operate the detector efficiently and accurately to prevent false alarms or missed detections. Regular training sessions and refresher courses can help ensure that personnel are up to date on the latest techniques and best practices for using single head needle detectors.

In addition to proper usage, regular maintenance of single head needle detectors is crucial for their longevity and accuracy. Routine maintenance tasks may include cleaning the detector, inspecting for wear and tear, and calibrating the equipment as needed. It is also important to keep the detector in good working condition by replacing any faulty parts or components promptly. By conducting regular maintenance checks, users can prevent equipment malfunctions and keep the detector functioning effectively.

Another important aspect of ensuring the safety of single head needle detectors is to perform regular quality control checks. This involves testing the detector's sensitivity and accuracy using known test objects, such as standardized metal needles or blades. By conducting regular quality control checks, users can verify that the detector is operating within acceptable parameters and is capable of detecting foreign objects reliably. Any deviations from the expected results should be investigated promptly to identify and rectify any issues with the detector.

Furthermore, it is essential to establish a comprehensive safety protocol for using single head needle detectors in the workplace. This may include designated areas for conducting inspections, proper handling procedures for detected foreign objects, and emergency response plans in case of equipment failure or malfunction. By implementing a robust safety protocol, users can minimize the risk of accidents and ensure a safe working environment for all personnel.

In conclusion, the proper usage and maintenance of single head needle detectors are critical for ensuring the safety of users and consumers. By following the manufacturer's guidelines, conducting regular maintenance checks, performing quality control tests, and establishing a comprehensive safety protocol, users can enhance the effectiveness and reliability of single head needle detectors. Ultimately, investing in the proper utilization and upkeep of these detectors can help prevent potential hazards and uphold the highest standards of safety in various industries.

Importance of regular training on single head needle detectors for staff members

In any industry, safety should always be a top priority. This is especially true in the food and pharmaceutical sectors, where contamination can have serious consequences for consumers. In order to ensure the safety of products and protect the wellbeing of staff members, the use of single head needle detectors is essential.

Single head needle detectors are crucial tools in the manufacturing process, as they help to detect any foreign objects within the product. These detectors are able to identify even the smallest pieces of metal, ensuring that contaminated products are not released into the market. By employing these devices, companies can maintain their commitment to quality and safety standards.

However, simply having single head needle detectors in place is not enough. Regular training for staff members on how to properly operate and maintain these devices is equally important. Without proper training, employees may not be able to effectively utilize the detectors, putting the safety of products at risk.

Training on single head needle detectors should cover a range of topics, including how to calibrate the device, how to interpret readings, and how to troubleshoot any issues that may arise. By ensuring that staff members are well-versed in the operation of these detectors, companies can guarantee their effectiveness in detecting contaminants.

Additionally, ongoing training is essential to keep staff members up-to-date on the latest technology and advancements in single head needle detectors. As technology continues to evolve, it is important that employees are informed of any changes or updates to the devices they are using. This will help to ensure that the detectors are being used to their full potential and are providing the maximum level of safety for products.

Furthermore, regular training on single head needle detectors can also help to prevent accidents and injuries in the workplace. By teaching employees how to properly handle and maintain these devices, companies can reduce the risk of equipment malfunctions and ensure the safety of their staff members.

In conclusion, the importance of regular training on single head needle detectors for staff members cannot be overstated. These devices play a critical role in ensuring the safety of products in the food and pharmaceutical industries, and it is essential that employees are properly trained in their operation. By investing in training for staff members, companies can safeguard the quality of their products, protect their consumers, and maintain a safe working environment for all employees.

Conclusion

In conclusion, it is evident that single head needle detectors play a crucial role in ensuring safety in various industries, particularly in the food and healthcare sectors. These devices provide an effective means of detecting and preventing potential hazards such as metal fragments in products, thus safeguarding consumers and employees from harm. By investing in and implementing single head needle detectors, organizations can demonstrate their commitment to upholding high standards of safety and quality. Ultimately, the importance of using these advanced detection technologies cannot be underestimated in today's fast-paced and demanding world. It is essential for businesses to prioritize safety measures and adapt to technological advancements to remain competitive and protect their reputation.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.