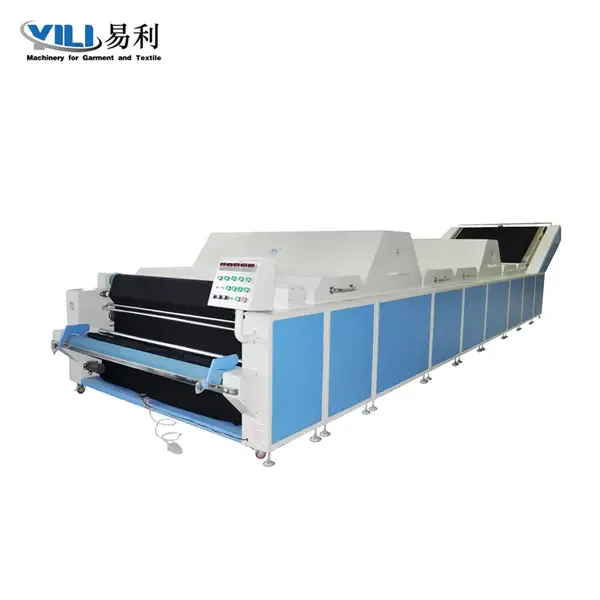

Function:

1.Electric heater preheating, heating mesh belt, prevent water droplets.

2.Double steam area, fabric shrinkage effect will be better ,machine work efficiency higher.

3.Four drying area. Drying is mainly by steam heating, electric heating is auxiliary. Not only for save energy but also meet the temperature requirements of different fabric.

4.Adopt strong cooling device, quickly cooling fabric, stabilize fabric size.

5.Vibration function allow the fiber to be fluffy naturally.

6.Spreading fabric 、Measurement、folding fabric.

Knit and woven ,a variety of general fabric.Especially suitable for pure cotton, silk, wool, linen, synthetic fiber and mixed textiles.

Feature:

1.Fully sealed unique design steam cover: no leakage of steam, reduce the steam consumption (save about 40% steam consumption than other type product), ensure no water dripping.

2.The steam cover is made of three layers of stainless steel,good heat preservation and thermal insulation effect.

3.Electronic eye monitoring releasing fabric , make sure fabric is in the tension-free state.

4.Step-less Frequency Conversion Timing.

5.Equipped with original imported electrical appliances, stable performance,machine is durable.

6.Use high temperature resistant Teflon mesh belt.

| Model |

YL-8800-SH |

| Voltage&Frequency |

AC 380V 50HZ |

| Steam consumption |

200kg/h |

| Steam pressure |

0.4-0.7 Mpa |

| Maximum roll fabric diameter |

40cm |

| Maximum working width |

2100mm |

| Working speed |

Adjustable,0-20m/min |

| Drying temperature |

Adjustable,≤200 ℃ |

| Drying heating power |

28kw |

| Total Power |

32.24kw |

| Boundary dimension |

10690*2610*2070mm |