Revolutionizing Textile Quality Control: The Impact Of Digital Fabric Inspection Machines

In the fast-paced world of textiles, quality control is of utmost importance to ensure the highest standards of production. With the emergence of digital fabric inspection machines, the industry is witnessing a revolution in how fabrics are inspected for defects and imperfections. This cutting-edge technology is changing the game for manufacturers, allowing for more efficient and accurate quality control processes. Join us as we delve into the impact of digital fabric inspection machines on the textile industry and discover how this innovative technology is shaping the future of textile quality control.

- The Evolution of Traditional Textile Quality Control Methods

The textile industry has always relied on traditional methods of quality control to ensure that fabrics meet the required standards. However, with the advancement of technology, a new player has entered the game - digital fabric inspection machines. These revolutionary devices are set to change the way textiles are inspected and provide a more accurate and efficient method of quality control.

Traditional textile quality control methods have involved manual inspection of fabrics, which can be time-consuming and prone to human error. Inspectors would need to visually examine each inch of fabric for imperfections such as tears, pulls, or inconsistencies in the weave. This process is not only labor-intensive but also subjective, as different inspectors may have varying opinions on what constitutes a defect.

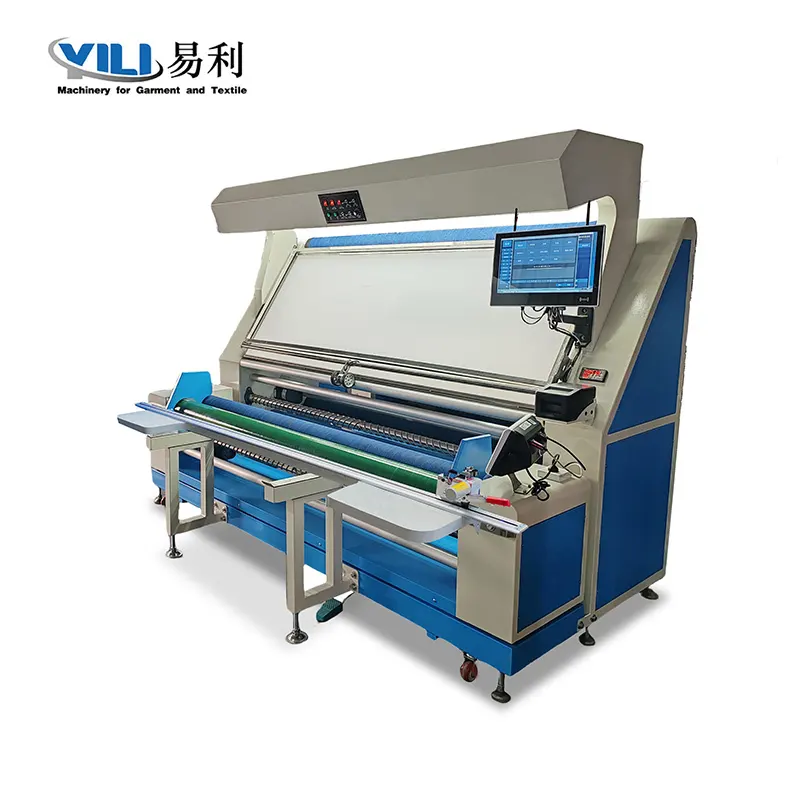

Digital fabric inspection machines, on the other hand, utilize cutting-edge technology to scan fabrics and identify imperfections with precision and speed. These machines are equipped with high-resolution cameras and sophisticated software that can detect even the smallest flaws in the fabric. By automating the inspection process, these machines eliminate the need for manual labor and provide an objective evaluation of the fabric's quality.

The impact of digital fabric inspection machines on the textile industry is significant. Not only do they reduce the time and cost associated with quality control, but they also improve the overall quality of the fabrics being produced. By catching defects early in the production process, manufacturers can avoid costly rework and ensure that only top-quality fabrics make it to the market.

Furthermore, digital fabric inspection machines offer additional benefits beyond just quality control. They can also help manufacturers track and analyze trends in fabric defects, allowing them to identify areas for improvement in their production processes. By collecting data on defects and trends, manufacturers can make informed decisions on how to optimize their operations and enhance the quality of their products.

In conclusion, digital fabric inspection machines are revolutionizing traditional textile quality control methods. By providing a more accurate, efficient, and objective way of inspecting fabrics, these machines are changing the game for manufacturers in the textile industry. With their ability to improve quality, reduce costs, and analyze trends, digital fabric inspection machines are set to become an essential tool for anyone looking to produce top-notch textiles.

- Advantages of Implementing Digital Fabric Inspection Machines

In the world of textile manufacturing, quality control plays a crucial role in ensuring that finished products meet the highest standards of excellence. One of the most revolutionary advancements in this arena is the implementation of digital fabric inspection machines. These state-of-the-art devices have transformed the way in which textiles are inspected for defects, ensuring a higher level of precision and efficiency in the production process.

One of the key advantages of implementing digital fabric inspection machines is the ability to detect defects with unparalleled accuracy. Traditional methods of fabric inspection often rely on human eyes to identify imperfections, which can be prone to error and inconsistency. With digital fabric inspection machines, however, defects such as stains, tears, or inconsistencies in the fabric weave can be pinpointed with precision, allowing manufacturers to address these issues quickly and effectively.

Another significant advantage of digital fabric inspection machines is the speed at which they can analyze large quantities of fabric. These machines are equipped with advanced software that can scan fabrics at rapid speeds, reducing the time and manpower required for inspection. This increased efficiency not only saves manufacturers time and money but also allows for a more streamlined production process.

Furthermore, digital fabric inspection machines offer a level of objectivity that is difficult to achieve through manual inspection methods. By eliminating the potential for human error and bias, these machines provide a more consistent and reliable assessment of fabric quality. This objectivity is essential in ensuring that finished products meet the stringent quality standards demanded by consumers and retailers.

In addition to their precision and efficiency, digital fabric inspection machines also offer a level of versatility that makes them indispensable in the textile industry. These machines can be customized to suit the specific needs of different fabrics, allowing manufacturers to tailor their inspection processes to the unique characteristics of each material. Whether inspecting delicate silk fabrics or heavy-duty denim, digital fabric inspection machines can provide a thorough analysis that meets the highest standards of quality control.

Overall, the implementation of digital fabric inspection machines has had a profound impact on the textile industry, revolutionizing the way in which fabrics are inspected for defects. With their unmatched accuracy, speed, objectivity, and versatility, these machines have become essential tools for manufacturers seeking to improve the quality of their products. By embracing this cutting-edge technology, textile manufacturers can ensure that their fabrics meet the highest standards of excellence, leading to greater customer satisfaction and industry success.

- How Digital Fabric Inspection Machines Work

In today's fast-paced textile industry, ensuring high-quality fabrics is crucial for companies looking to maintain their competitive edge. Traditional methods of fabric inspection often involved labor-intensive manual processes that were not only time-consuming but also prone to human error. However, with the advent of digital fabric inspection machines, the landscape of textile quality control has been revolutionized.

Digital fabric inspection machines utilize state-of-the-art technology to detect and analyze defects in fabrics with unmatched precision and efficiency. These machines are equipped with high-resolution cameras and advanced image processing software that can identify even the most minute imperfections in the fabric. By detecting defects such as holes, stains, or weaving irregularities, these machines help manufacturers identify and rectify issues before the fabric is sent for further processing.

One of the key features of digital fabric inspection machines is their ability to provide real-time feedback to operators. As the fabric passes through the machine, it is scanned and analyzed in a matter of seconds, allowing operators to quickly identify any defects and take immediate corrective action. This real-time feedback not only speeds up the inspection process but also helps reduce the likelihood of defects going unnoticed, ultimately leading to higher-quality end products.

Furthermore, digital fabric inspection machines offer a level of consistency and reliability that is unmatched by traditional inspection methods. Human inspectors may inadvertently overlook certain defects or inconsistencies, leading to inconsistencies in the final product. In contrast, digital fabric inspection machines follow a preset set of criteria and parameters, ensuring that every inch of fabric is thoroughly inspected according to the same standards. This consistency not only helps in maintaining high-quality standards but also ensures that all fabrics meet the same level of quality control.

Another advantage of digital fabric inspection machines is their ability to store and analyze data for future reference. By recording and storing information about each fabric roll that passes through the machine, manufacturers can track the quality of their fabrics over time and identify patterns or trends in defects. This data can be used to pinpoint areas for improvement in the production process, leading to more efficient and reliable manufacturing operations.

In conclusion, digital fabric inspection machines have had a significant impact on the textile industry by revolutionizing the way fabrics are inspected and ensuring high-quality standards are met. By leveraging advanced technology and real-time feedback, these machines offer unmatched precision, consistency, and reliability in fabric inspection. As the textile industry continues to evolve, digital fabric inspection machines will play a crucial role in helping manufacturers maintain their competitive edge and deliver superior quality products to consumers.

- Improving Efficiency and Accuracy in Textile Quality Control

In today's fast-paced and highly competitive textile industry, ensuring product quality is essential for maintaining customer satisfaction and staying ahead of the competition. One of the key technologies revolutionizing textile quality control is the digital fabric inspection machine. These innovative machines are changing the game by improving efficiency and accuracy in the inspection process, ultimately leading to higher quality products and increased productivity.

Digital fabric inspection machines have transformed the way textile manufacturers inspect fabrics for defects and inconsistencies. In the past, quality control was a time-consuming and labor-intensive process that relied heavily on manual inspection. This method was not only inefficient but also prone to human error, leading to inconsistencies in product quality. With digital fabric inspection machines, manufacturers can now automate the inspection process, reducing the need for human intervention and improving the accuracy of defect detection.

One of the key advantages of digital fabric inspection machines is their ability to scan fabrics at high speeds with unparalleled precision. These machines use advanced imaging technology to capture detailed images of the fabric, allowing for thorough inspection of even the smallest defects. By analyzing these images, manufacturers can quickly identify and categorize defects, enabling them to take corrective action before the fabric is used in production.

Furthermore, digital fabric inspection machines can also store and analyze data on fabric defects, allowing manufacturers to track trends and patterns over time. This data-driven approach to quality control enables manufacturers to identify potential issues before they become widespread, ultimately saving time and resources in the long run.

In addition to improving efficiency and accuracy, digital fabric inspection machines also offer other benefits to textile manufacturers. For example, these machines can help reduce waste by identifying and removing defective fabrics before they are used in production. This not only saves materials but also minimizes the risk of producing subpar products that could damage a company's reputation.

Overall, digital fabric inspection machines are revolutionizing textile quality control by improving efficiency and accuracy in the inspection process. By automating and streamlining the inspection process, manufacturers can produce higher quality products, reduce waste, and ultimately stay competitive in today's fast-paced industry. As technology continues to advance, we can expect to see even more innovations in textile quality control, further enhancing product quality and customer satisfaction.

- The Future of Fabric Inspection: Embracing Digital Technology

The textile industry has long been a key player in global manufacturing, providing countless products that we use on a daily basis. From clothing to household items, textiles are an essential part of our lives. However, ensuring the quality of these products has always been a challenge for manufacturers. Traditionally, fabric inspection has been a labor-intensive process, requiring skilled workers to meticulously examine each piece of fabric for defects.

But with the advent of digital technology, the future of fabric inspection is being revolutionized. Digital fabric inspection machines are changing the game, providing a more efficient and accurate method of quality control. These machines utilize advanced imaging technology to scan and analyze fabric for defects, allowing manufacturers to quickly identify and address quality issues.

One of the key advantages of digital fabric inspection machines is their speed and precision. These machines can scan large volumes of fabric in a fraction of the time it would take a human inspector, while also providing a more detailed and accurate analysis. This not only saves time and labor costs for manufacturers, but also ensures a higher level of quality control.

In addition to speed and precision, digital fabric inspection machines also offer increased consistency and reliability in the inspection process. Human inspectors may vary in their ability to identify defects, leading to inconsistencies in quality control. With digital machines, the inspection process is standardized, ensuring that every piece of fabric is evaluated in the same way. This consistency helps manufacturers maintain a high level of quality across their products.

Furthermore, digital fabric inspection machines can provide valuable data and insights to manufacturers. By analyzing the data collected during the inspection process, manufacturers can identify trends and patterns in fabric defects, allowing them to implement proactive measures to prevent issues in the future. This data-driven approach to quality control can lead to improved efficiency and cost savings for manufacturers.

Overall, the impact of digital fabric inspection machines on the textile industry is significant. By embracing this technology, manufacturers can streamline their quality control processes, improve product quality, and ultimately enhance customer satisfaction. As digital technology continues to evolve, the future of fabric inspection looks bright, promising even greater advancements in quality control for the textile industry.

Conclusion

In conclusion, the emergence of digital fabric inspection machines has undoubtedly revolutionized textile quality control in the industry. These advanced technologies have significantly improved efficiency, accuracy, and consistency in identifying and resolving defects in fabrics, ultimately leading to higher quality products and increased customer satisfaction. As more companies continue to adopt these innovative tools, we can expect to see further advancements in textile quality control and ultimately a more streamlined and competitive textile industry. The future of textile quality control is indeed bright, thanks to the transformative impact of digital fabric inspection machines.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.