Maximizing Efficiency: The Benefits Of Using A Fabric Inspection Machine

Are you tired of wasting time and resources on manually inspecting fabrics? Look no further than a Fabric Inspection Machine to streamline your process and maximize efficiency. In this article, we delve into the numerous benefits of utilizing this advanced technology and how it can revolutionize your operations. Read on to discover how a Fabric Inspection Machine can elevate your business to the next level.

- The Importance of Efficient Fabric Inspection

Fabric inspection is a crucial step in the textile manufacturing process, ensuring that only high-quality fabrics are used in the production of garments and other textile products. The importance of efficient fabric inspection cannot be overstated, as it not only helps in avoiding costly errors and rework but also ensures that the final product meets the desired quality standards.

One of the key benefits of using a fabric inspection machine is the increased efficiency it brings to the inspection process. These machines are designed to examine fabrics quickly and accurately, identifying any defects or imperfections that may be present. By automating the inspection process, fabric inspection machines can significantly reduce the time and labor required for manual inspection, allowing manufacturers to inspect larger quantities of fabric in a shorter amount of time.

In addition to improved efficiency, fabric inspection machines also offer greater consistency and accuracy in the inspection process. Human inspectors may miss defects or inconsistencies due to fatigue or human error, but fabric inspection machines are programmed to detect even the smallest imperfections in the fabric. This ensures that all fabrics are thoroughly inspected and any defects are identified and addressed before they can affect the quality of the final product.

Another advantage of using a fabric inspection machine is the ability to customize the inspection process to meet specific requirements. Fabric inspection machines can be programmed to inspect fabrics for a wide range of criteria, including color consistency, pattern matching, and fabric weight. This level of customization ensures that manufacturers can tailor the inspection process to meet their individual needs and quality standards.

Furthermore, fabric inspection machines can help manufacturers identify and address defects early in the production process, reducing the likelihood of costly rework or product recalls. By catching defects before they are integrated into the final product, fabric inspection machines can help manufacturers save time and money while maintaining the overall quality of their products.

In conclusion, the importance of efficient fabric inspection cannot be overstated in the textile manufacturing industry. Fabric inspection machines offer a range of benefits, including increased efficiency, consistency, accuracy, customization, and defect prevention. By investing in a fabric inspection machine, manufacturers can improve the quality of their products, reduce production costs, and ultimately enhance customer satisfaction. Fabric inspection machines are a valuable tool for any textile manufacturer looking to maximize efficiency and maintain high-quality standards in their production process.

- Streamlining Production Processes with a Fabric Inspection Machine

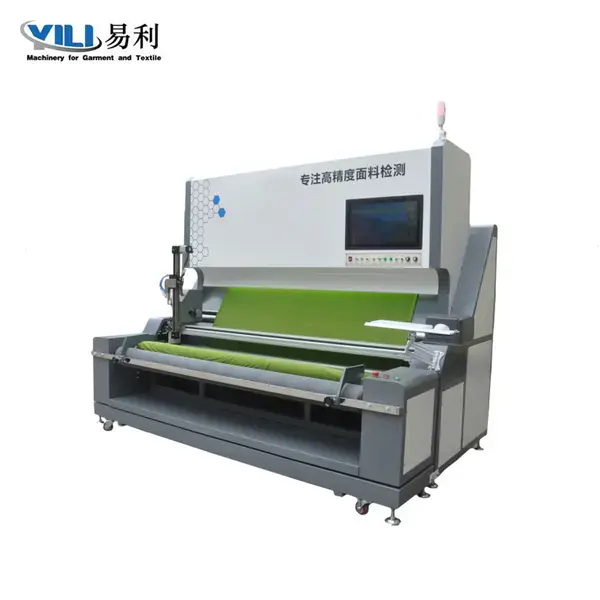

In today's fast-paced textile industry, maximizing efficiency and streamlining production processes are crucial for staying competitive. One key tool that can help achieve these goals is the fabric inspection machine. This advanced piece of equipment is designed to carefully examine fabrics for defects or imperfections, ensuring that only high-quality materials are used in the manufacturing process.

The fabric inspection machine offers a range of benefits for textile manufacturers, from saving time and labor costs to improving overall product quality. By automating the inspection process, operators can quickly and accurately identify any issues with the fabric, allowing them to address problems before they escalate. This not only helps to prevent defects in the final product but also reduces the risk of costly rework or returns.

One of the major advantages of using a fabric inspection machine is its ability to increase production efficiency. By detecting defects early on, manufacturers can make immediate adjustments to their processes, such as adjusting tension settings or alignment, to ensure that the fabric meets quality standards. This helps to avoid unnecessary delays and bottlenecks in production, ultimately speeding up the manufacturing process and increasing output.

Additionally, fabric inspection machines offer consistent and reliable results, further enhancing product quality. These machines are equipped with advanced technology, such as high-resolution cameras and intelligent sensors, that can detect even the smallest imperfections in the fabric. This level of precision ensures that each piece of fabric is thoroughly inspected, leading to a higher level of quality control and customer satisfaction.

Moreover, the fabric inspection machine helps to reduce the risk of human error in the inspection process. Manual inspection methods can be time-consuming and subjective, leaving room for mistakes or oversights. With a fabric inspection machine, however, operators can rely on precise and accurate results, minimizing the likelihood of defects slipping through the cracks.

Overall, investing in a fabric inspection machine is a smart choice for textile manufacturers looking to maximize efficiency and quality in their production processes. By automating the inspection process, reducing the risk of defects, and increasing production speed, this advanced equipment can help businesses stay competitive in a rapidly evolving industry.

In conclusion, the fabric inspection machine is a valuable asset for textile manufacturers seeking to improve their production processes and deliver top-quality products to their customers. By leveraging the benefits of this advanced equipment, companies can streamline their operations, increase efficiency, and ultimately achieve greater success in the competitive textile market.

- Enhancing Quality Control Through Automated Inspection

In today's fast-paced textile industry, speed and efficiency are crucial in ensuring high-quality products reach the market in a timely manner. Fabric inspection machines have become an indispensable tool for manufacturers looking to enhance their quality control processes through automated inspection.

Fabric inspection machines are designed to accurately and efficiently inspect fabric for any defects or inconsistencies. These machines can detect flaws such as color variations, holes, tears, and fabric irregularities, allowing for immediate correction or removal of the flawed material. This automated inspection process not only ensures that only top-quality fabric is used in production but also saves valuable time and resources that would otherwise be wasted on manual inspection.

One of the key benefits of using a fabric inspection machine is the increase in productivity and efficiency. With the ability to inspect fabric at a much faster rate than manual inspection, manufacturers can significantly reduce the time it takes to inspect large quantities of fabric. This allows for quicker turnaround times in production, ultimately leading to increased output and profitability for the company.

Additionally, fabric inspection machines can help minimize the risk of human error in the inspection process. By automating the inspection process, manufacturers can eliminate the subjective judgment that comes with manual inspection, ensuring a more consistent and reliable evaluation of fabric quality. This reduction in human error can lead to improved overall product quality and fewer defects in the final product.

Furthermore, fabric inspection machines can also provide valuable data and insights that can be used to enhance the manufacturing process. By collecting data on fabric quality and defects, manufacturers can identify trends and patterns that may indicate underlying issues in the production process. This proactive approach to quality control can help prevent future defects and improve overall product quality over time.

In conclusion, fabric inspection machines offer a wide range of benefits for manufacturers looking to maximize efficiency and enhance quality control in their production processes. By automating the inspection process, manufacturers can increase productivity, minimize the risk of human error, and gather valuable data to improve overall product quality. With the use of fabric inspection machines, manufacturers can stay ahead of the competition and deliver top-quality products to the market with confidence.

- Saving Time and Improving Accuracy in Fabric Evaluation

In the fast-paced world of textile manufacturing, efficiency and accuracy are crucial. Fabric evaluation is a vital step in the production process, as it ensures that the quality of the fabric meets the required standards before it is used in garments or other products. However, traditional fabric evaluation methods are often time-consuming and prone to human error. This is where fabric inspection machines come in, offering a solution that saves time and improves accuracy in fabric evaluation.

Fabric inspection machines are advanced tools that use technology to analyze fabrics quickly and accurately. These machines are equipped with sensors and cameras that can detect defects in the fabric, such as holes, stains, or inconsistencies in the weave. By automating the inspection process, fabric inspection machines eliminate the need for manual evaluation, saving valuable time and reducing the risk of human error.

One of the key benefits of using a fabric inspection machine is the time savings it provides. Traditional fabric evaluation methods involve manual inspection by trained personnel, which can be a time-consuming process. With a fabric inspection machine, fabrics can be evaluated in a fraction of the time it would take a human inspector. This allows manufacturers to speed up their production process and meet tight deadlines more efficiently.

In addition to saving time, fabric inspection machines also improve the accuracy of fabric evaluation. Human inspectors are prone to fatigue and can miss defects in the fabric, leading to costly mistakes and delays in production. Fabric inspection machines, on the other hand, are designed to detect even the smallest defects in the fabric, ensuring that only top-quality materials are used in the manufacturing process. This not only saves money in the long run but also helps to maintain a high standard of quality in the final product.

Another advantage of using fabric inspection machines is their versatility. These machines can be programmed to inspect fabrics of various types, sizes, and colors, making them suitable for a wide range of manufacturing applications. Whether you are producing clothing, upholstery, or technical textiles, a fabric inspection machine can help you ensure that your fabrics meet the required standards for quality and consistency.

Moreover, fabric inspection machines can also help manufacturers reduce waste and improve sustainability. By detecting defects early in the production process, these machines prevent the use of flawed fabrics in the final product, reducing the amount of waste generated. This not only saves money on materials but also helps to minimize the environmental impact of textile production.

In conclusion, fabric inspection machines offer a range of benefits for manufacturers looking to maximize efficiency in fabric evaluation. By saving time, improving accuracy, and promoting sustainability, these advanced tools can help companies streamline their production process and deliver high-quality products to market faster. As technology continues to advance, fabric inspection machines will play an increasingly important role in the textile industry, ensuring that fabrics meet the highest standards of quality and consistency.

- Maximizing Output and Minimizing Waste with Technology in Textile Manufacturing

In the fast-paced world of textile manufacturing, efficiency is key. Companies are constantly looking for ways to maximize output and minimize waste in order to stay competitive in the market. One solution that has been gaining popularity is the use of fabric inspection machines.

Fabric inspection machines are innovative tools that help manufacturers identify and rectify defects in fabrics before they are cut and sewn into finished products. By using advanced technology such as cameras and sensors, these machines can detect even the smallest imperfections in the fabric, such as holes, tears, or stains.

One of the main benefits of using a fabric inspection machine is the increase in productivity it brings. By catching defects early on in the manufacturing process, manufacturers can avoid costly mistakes and delays down the line. This not only saves time and money, but also ensures that customers receive high-quality products that meet their expectations.

In addition to maximizing efficiency, fabric inspection machines also help minimize waste. By identifying and sorting out defective fabrics, manufacturers can reduce the amount of material that ends up in the landfill. This not only benefits the environment, but also helps companies save on costs associated with purchasing and disposing of excess materials.

Another advantage of using fabric inspection machines is the improvement in overall product quality. By ensuring that only defect-free fabrics are used in production, manufacturers can create products that are more consistent and reliable. This can help build customer trust and loyalty, leading to increased sales and brand reputation.

Furthermore, fabric inspection machines can also help manufacturers comply with industry regulations and standards. By identifying and documenting defects, manufacturers can demonstrate that their products meet quality requirements, giving them a competitive edge in the market.

Overall, the use of fabric inspection machines has revolutionized the textile manufacturing industry. By maximizing output, minimizing waste, and improving product quality, these machines have become essential tools for companies looking to stay ahead in a competitive market. With the right technology and processes in place, manufacturers can reap the benefits of increased efficiency and profitability.

Conclusion

In conclusion, utilizing a fabric inspection machine can bring a multitude of benefits to textile manufacturers and designers alike. From improving efficiency and accuracy in quality control to reducing human error and increasing productivity, this advanced technology offers a competitive edge in today's fast-paced industry. By investing in a fabric inspection machine, companies can streamline their production processes, optimize their resources, and ultimately deliver superior products to their customers. In a world where precision and efficiency are paramount, embracing this innovative tool is not just a smart decision – it's a strategic move towards success.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.