Stable & High quality

Yili has its own production line, controls every production process, and better controls the equipment quality and production cycle; the electrical components are all imported brands to ensure the stability of the equipment.

Smart & Efficient

Yili understands the pain points of the textile and garment industry, increases investment in traditional equipment intelligence and automation upgrade technology, greatly improves production efficiency and quality for you, and promotes intelligent production.

Environmental friendly & Energy saving

Yili has a number of energy-saving and environmental protection structures with national patents, and many types of equipment are leaders in the industry. The original technology ensures excellent energy-saving and environmental protection effects.

Customization & Informatization

Yili has 30 years of experience in R&D, manufacturing, sales and service of clothing equipment, with automatic R&D capabilities, and can flexibly provide customers with customized equipment to meet specific production needs.

Related Products

More items about spreading machine

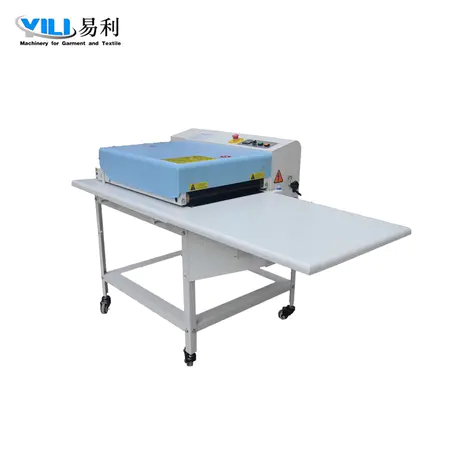

Automatic fabric spreading machine

Yili (Zhaoqing) Intelligent Technology Co., Ltd. was established in 1992 (formerly known as a joint venture between the Duanzhou District Government of Zhaoqing City and Hong Kong Tailifa Company). A high-tech enterprise, it is committed to realizing the intelligent finishing of the textile and garment industry, opening up the key links of intelligent manufacturing of textile and garment, integrating R&D, manufacturing, sales and service. Since its establishment, it has always attached great importance to technological innovation and product development. Has a number of high-tech product certificates, 5 national invention patents, and obtained CE certification and ISO9001 certification.

Since the launch of the smart fabric testing and smart ironing projects in 2018, the team has visited 100+ customer sites and conducted in-depth discussions with senior fabric experts in the textile industry to understand industry needs. Yili is an all-round company with industry experience and technology research and development capabilities.

Yili adheres to the vision of "making the textile and apparel industry intelligent and green", takes products as the core, wins credibility with quality, leads the future with innovation, continuously improves product value, and is committed to providing modern solutions for the textile and apparel industry. The pioneer of intelligent equipment in the textile and garment industry, assists the era of Industry 4.0 with technological innovation, and jointly builds intelligent new manufacturing.

The difference between automatic spreader and manual spreader

Automatic spreading machine, also known as digital intelligent spreading machine, is a professional spreading equipment with automatic conveying, cutting, sewing and positioning functions. The whole machine adopts the advanced technology of transmission, control, measurement and electrical components, adopts PLC programmable controller and man-machine interface for configuration, and is supplemented by electronic vacuum disc and grating ruler for measurement. The automatic spreading machine is a product that realizes digitalization and intelligence, and is an integrated high-tech product.

The traditional spreading method is to manually spread the material piece by piece, while the automatic spreading machine can spread the material continuously and quickly. In addition, the automatic spreading machine also has the functions of cutting, sewing and positioning. Use PLC programmable controller and man-machine interface to set up, so that the whole working process can be realized automatically.

What are the characteristics of the spreading machine?

(1) Remove the wrinkles of the fabric and release the tension of the fabric. Bucket-type automatic loosening equipment can timely and quickly loosen the fabric and fully release the tension of the fabric. In this process, the skewed material of the fabric can also be corrected to reduce the loss of the fabric during the spreading process. When the combined roller sends out the fabric, the combined roller can open the fabric in the undulating direction and remove fabric wrinkles.

(2) Difficult fabrics can also be delivered in a stable state. In order to smoothly send out the fabrics that are prone to load, a conveyor-type fabric delivery device is used. The vibration device on the conveyor belt can release the tension of the fabric when it is sent out, so that the fabric is more stable.

(3) Simple operation and simple setting. On the LCD touch screen, you can easily set various spreading conditions such as spreading length setting, phase spreading setting (6 different spreading lengths), total number of spreading layers, etc.

Working principle of automatic spreading machine

An automatic spreading machine is a machine that uses a robotic arm to spread the fabric and fix it on the workbench. It can greatly improve production efficiency, reduce manual labor intensity, and help ensure product quality. The use of automatic spreading machines can greatly improve production efficiency, reduce manual labor intensity, and help ensure product quality. Therefore, more and more companies choose to use automatic spreading machines to produce fabrics.

The working principle of the automatic spreading machine is to spread the fabric through the mechanical arm and fix it on the workbench. When the fabric is spread and fixed on the workbench, the robotic arm will continue to move forward until the fabric is fully spread. After that, the robotic arm will slowly move to the next position and repeat the above operation until the fabric is fully spread.

User Reviews

What users say about Us

Frequently Asked Question

Do you have any question?

Because it can Spread the rolled fabric to multi-layer for cutting process use.

We Driven by servo motor, the operation is more accurate.

Automatic type can save labor cost,improve working efficiency.

.jpg?imageView2/1/w/450/h/450/format/webp)