Stable & High quality

Yili has its own production line, controls every production process, and better controls the equipment quality and production cycle; the electrical components are all imported brands to ensure the stability of the equipment.

Smart & Efficient

Yili understands the pain points of the textile and garment industry, increases investment in traditional equipment intelligence and automation upgrade technology, greatly improves production efficiency and quality for you, and promotes intelligent production.

Environmental friendly & Energy saving

Yili has a number of energy-saving and environmental protection structures with national patents, and many types of equipment are leaders in the industry. The original technology ensures excellent energy-saving and environmental protection effects.

Customization & Informatization

Yili has 30 years of experience in R&D, manufacturing, sales and service of clothing equipment, with automatic R&D capabilities, and can flexibly provide customers with customized equipment to meet specific production needs.

Related Products

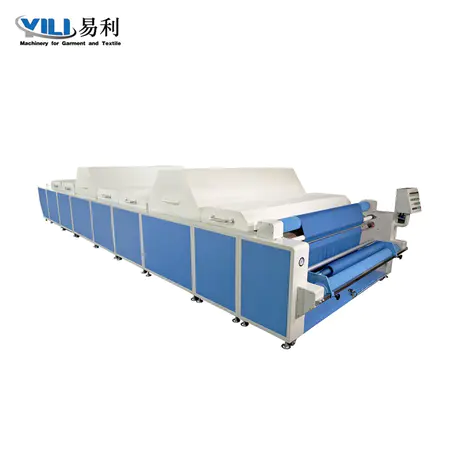

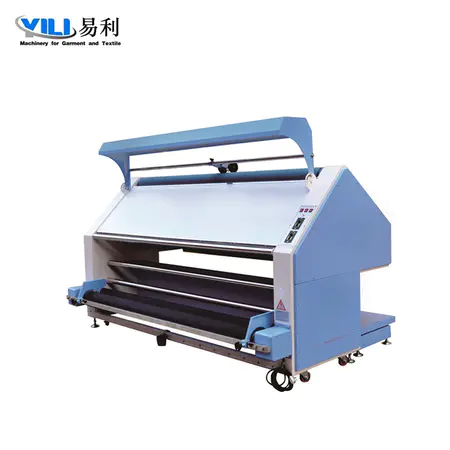

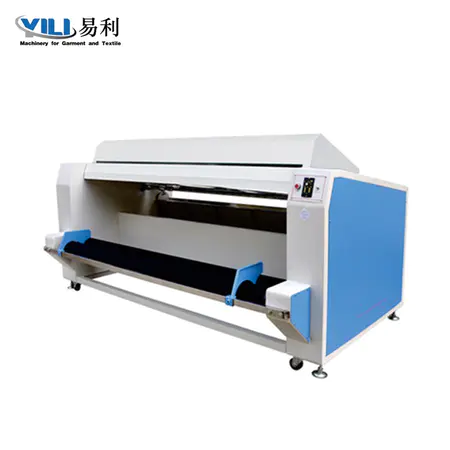

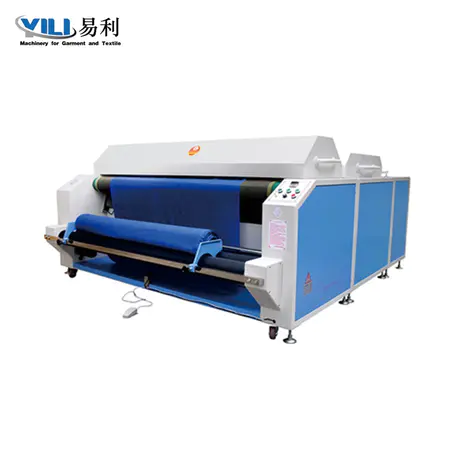

More items about fabric shrinking machine

Fabric pre-treatment machine ,fabric finishing machinery,fabric sponging machine

Yili (Zhaoqing) Intelligent Technology Co., Ltd. was established in 1992 (formerly known as a joint venture between the Duanzhou District Government of Zhaoqing City and Hong Kong Tailifa Company). A high-tech enterprise, it is committed to realizing the intelligent finishing of the textile and garment industry, opening up the key links of intelligent manufacturing of textile and garment, integrating R&D, manufacturing, sales and service. Since its establishment, it has always attached great importance to technological innovation and product development. Has a number of high-tech product certificates, 5 national invention patents, and obtained CE certification and ISO9001 certification.

Since the launch of the smart fabric testing and smart ironing projects in 2018, the team has visited 100+ customer sites and conducted in-depth discussions with senior fabric experts in the textile industry to understand industry needs. Yili is an all-round company with industry experience and technology research and development capabilities.

Yili adheres to the vision of "making the textile and apparel industry intelligent and green", takes products as the core, wins credibility with quality, leads the future with innovation, continuously improves product value, and is committed to providing modern solutions for the textile and apparel industry. The pioneer of intelligent equipment in the textile and garment industry, assists the era of Industry 4.0 with technological innovation, and jointly builds intelligent new manufacturing.

Working principle of fabric shrinking machine

fabric shrinking machine is in a certain temperature, humidity and pressure,fabric is the tension-free state, with the help of the fabric itself elastic shrinkage deformation ,textile and fiber penetration and swelling principle, eliminate the potential shrinkage of fabric, complete the shrinking work.

Advantages of fabric shrinking machine

1. Fabric shrinkage processing is to make the untreated fabric soft, and through the adjustment of the skew of silk yarn, the size of the original fabric to reduce the sewing process, due to the fabric by sewing and ironing shrinkage.

2. Prevent the size or shape of the clothes produced, so that you do not have to consider the problem of fabric stretching and shrinking during the manufacture of clothing before you design.

3. After shrinkage processing, the size of the cloth is stable, excellent hand feel, and after ironing again is not easy to shrink, this treatment makes the product quality to achieve the best, and the added value is increased.

Features of Yili fabric shrinking machine

National patent steam chamber&Exhaust water vapor in the downward design:Internal unique structure to ensure no water vapor dripping.Fully sealed unique design steam cover: no leakage of steam, steam cyclic utilization,reduce the steam consumption.

User Reviews

What users say about Us

Frequently Asked Question

Do you have any question?

Can reduce fabric shrinkage rate,fix fabric size.

Save 40% steam consumption than other brand,ensure no water dripping.

Fabric shrinking machine is in a certain temperature, humidity and pressure,fabric is the tension-free state, with the help of the fabric itself elastic shrinkage deformation ,textile and fiber penetration and swelling principle, eliminate the potential shrinkage of fabric, complete the shrinking work.