The Efficiency Of An Automatic Slitting Machine: Streamlining Production Processes

Are you looking to maximize productivity and streamline your production processes? Look no further than our article on “The Efficiency of an Automatic Slitting Machine." Discover how this cutting-edge technology can revolutionize your operations and enhance efficiency like never before. Dive into a detailed analysis of the benefits and advantages of utilizing automatic slitting machines to boost production. Don't miss out on this insightful read that will take your business to the next level.

- Understanding the Importance of Automating Slitting Processes

The demand for efficiency and productivity in the manufacturing industry has never been greater. In order to stay competitive in today's fast-paced market, companies must constantly look for ways to streamline their production processes. One such method is by utilizing automatic slitting machines to automate the process of cutting materials into smaller, more manageable sizes.

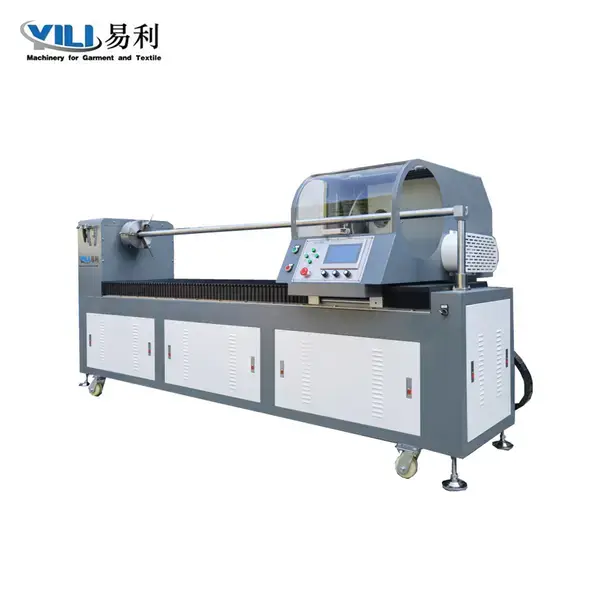

An automatic slitting machine is a specialized piece of equipment that is designed to accurately and efficiently cut materials such as paper, plastic, metal, or fabric into smaller widths. These machines are equipped with advanced technology and controls that allow for precise cutting and high-speed operation. By automating the slitting process, companies can significantly increase their production output while reducing labor costs and potential errors.

One of the key benefits of using an automatic slitting machine is the increased efficiency it provides. Manual slitting processes are often slow and labor-intensive, requiring operators to carefully measure and cut materials by hand. This can lead to inconsistencies in the finished product and wasted materials. With an automatic slitting machine, these issues are eliminated as the machine can accurately and consistently cut materials to the desired width with minimal human intervention.

In addition to improving efficiency, automatic slitting machines also offer other advantages such as increased precision and accuracy. These machines are able to make clean and precise cuts, ensuring that the finished products meet the required specifications. This level of precision is essential for industries such as printing, packaging, and textiles, where even a small error in cutting can lead to defects in the final product.

Furthermore, automatic slitting machines can help companies save on labor costs by reducing the need for manual labor in the production process. By automating the slitting process, companies can reallocate their resources to other areas of the business, leading to increased productivity and profitability. Additionally, the consistent and reliable performance of automatic slitting machines can help reduce waste and improve overall quality control.

Another important aspect of automatic slitting machines is their versatility and flexibility. These machines can be easily programmed to accommodate a wide range of materials and cutting specifications, making them ideal for businesses that work with various types of materials. Whether cutting paper rolls, plastic film, or metal sheets, automatic slitting machines can adapt to different production requirements with ease.

Overall, the implementation of an automatic slitting machine can have a significant impact on a company's production processes. By understanding the importance of automating the slitting process, businesses can not only improve efficiency and productivity but also enhance the quality and consistency of their products. With the right equipment and technology in place, companies can stay ahead of the competition and meet the demands of today's fast-paced market.

- Features and Benefits of an Automatic Slitting Machine

In today's fast-paced manufacturing industry, time is of the essence. Companies are constantly looking for ways to improve efficiency and streamline their production processes to stay competitive in the market. One way to achieve this is by investing in an automatic slitting machine. This state-of-the-art equipment has revolutionized the way materials are cut and processed, offering a plethora of features and benefits that can significantly enhance productivity and reduce wastage.

One of the key features of an automatic slitting machine is its precision cutting capabilities. Unlike manual cutting methods, which are prone to human error and inconsistencies, automatic slitting machines are equipped with advanced technology that ensures accurate and consistent cuts every time. This not only improves the quality of the finished product but also minimizes material wastage, saving both time and money in the long run.

Furthermore, automatic slitting machines are designed for high-speed operation, allowing for faster processing of materials and increased production output. This speed and efficiency can help companies meet tight deadlines and fulfill customer orders in a timely manner, ultimately enhancing customer satisfaction and retention.

Another benefit of automatic slitting machines is their versatility. These machines can be easily adjusted to accommodate different materials, thicknesses, and widths, making them suitable for a wide range of applications across various industries. Whether you need to cut paper, plastic, metal, or fabric, an automatic slitting machine can handle the job with precision and ease.

In addition to improving efficiency and productivity, automatic slitting machines also provide a safer working environment for employees. By automating the cutting process, workers are no longer exposed to the risks associated with manual cutting methods, such as sharp blades and repetitive strain injuries. This not only protects the well-being of employees but also reduces the likelihood of accidents and downtime in the production line.

Overall, the benefits of investing in an automatic slitting machine are clear. From precision cutting and high-speed operation to versatility and safety, this state-of-the-art equipment offers a myriad of features that can transform the way materials are processed in a manufacturing setting. By incorporating an automatic slitting machine into your production process, you can boost efficiency, reduce costs, and stay ahead of the competition in today's competitive market.

- Enhancing Production Efficiency with Automated Slitting Technology

In today's rapidly evolving industry landscape, the demand for increased production efficiency is higher than ever. Manufacturers are constantly searching for innovative solutions to streamline their production processes and gain a competitive edge in the market. One such solution that has been gaining traction in recent years is the use of automatic slitting machines.

Automatic slitting machines are cutting-edge technology that enhances production efficiency by automating the process of cutting and slitting materials. These machines are equipped with advanced sensors and software that allow them to precisely and efficiently slice through various types of materials with minimal human intervention. This not only speeds up the production process but also reduces the risk of errors and wastage.

One of the key advantages of automatic slitting machines is their ability to handle a wide range of materials, including paper, plastic, metal, and textiles. This versatility makes them an invaluable asset for manufacturers in a variety of industries, from packaging and printing to automotive and electronics. With the ability to cut through materials of varying thicknesses and sizes, automatic slitting machines offer a level of flexibility that traditional manual cutting methods simply cannot match.

Another major benefit of automatic slitting machines is their high level of precision. These machines are capable of cutting materials with utmost accuracy, ensuring that each piece is uniform in size and shape. This not only improves the overall quality of the finished product but also reduces the need for rework or corrections, saving both time and money in the long run.

Furthermore, automatic slitting machines offer a significant boost to productivity. By automating the cutting process, these machines can significantly reduce the time it takes to complete each job. This allows manufacturers to increase their output without the need for additional manpower, leading to cost savings and enhanced profitability. Additionally, the consistent and reliable performance of automatic slitting machines helps manufacturers meet tight production deadlines and deliver orders on time, leading to improved customer satisfaction and loyalty.

In conclusion, the efficiency of an automatic slitting machine lies in its ability to enhance production efficiency by streamlining processes and increasing productivity. With their advanced technology, precision cutting capabilities, and versatility, these machines have become essential tools for manufacturers looking to stay ahead in today's competitive market. By investing in automatic slitting technology, manufacturers can not only improve their operational efficiency but also position themselves for long-term success in an ever-evolving industry landscape.

- Optimizing Workflow and Minimizing Errors in Slitting Operations

An automatic slitting machine is a crucial piece of equipment in industries that require precision cutting and processing of materials such as paper, plastic, metal, or fabric. These machines are designed to optimize workflow and minimize errors in slitting operations, making them an essential tool for streamlining production processes.

One of the key advantages of using an automatic slitting machine is its ability to efficiently process large volumes of material in a short amount of time. By automating the cutting process, these machines are able to achieve high levels of productivity and throughput, resulting in a significant increase in overall efficiency. This is particularly beneficial for industries that rely on quick turnaround times and tight production schedules.

In addition to improving workflow, automatic slitting machines also help minimize errors in the cutting process. The automated nature of these machines means that they are able to consistently produce accurate cuts with minimal variation, reducing the risk of defects and waste. This not only saves time and resources but also improves the overall quality of the final product.

Furthermore, automatic slitting machines are equipped with advanced sensors and monitoring systems that allow operators to closely track and control the cutting process. This real-time feedback enables operators to make quick adjustments as needed, ensuring that the machine is operating at peak efficiency and producing high-quality results. Additionally, these machines are often integrated with software systems that can analyze production data and provide insights for further optimization.

Another key benefit of automatic slitting machines is their versatility in handling a wide range of materials and thicknesses. Whether cutting thin films or thick sheets, these machines are equipped with the necessary tools and adjustments to accommodate various types of materials, ensuring a smooth and efficient production process. This flexibility allows manufacturers to easily switch between different products without the need for extensive retooling or reprogramming.

Overall, the efficiency of an automatic slitting machine lies in its ability to optimize workflow and minimize errors in slitting operations. By streamlining production processes and providing precise cuts with minimal variation, these machines play a critical role in enhancing productivity, reducing waste, and improving the overall quality of products. As technology continues to advance, automatic slitting machines will undoubtedly become an indispensable tool for manufacturers looking to stay competitive in today's fast-paced and demanding market.

- Achieving Cost Savings and Improved Output Through Automation

In today's fast-paced manufacturing industry, companies are constantly seeking ways to improve efficiency and cut costs in order to stay competitive. One key way to achieve these goals is through the use of automatic slitting machines. These machines are designed to streamline production processes by automating the process of cutting materials into smaller, more manageable strips.

By eliminating the need for manual labor, automatic slitting machines can help companies achieve significant cost savings. Labor costs can be one of the biggest expenses for a manufacturing company, so automating tasks such as slitting can have a major impact on the bottom line. In addition, automatic machines are able to work much faster and more consistently than humans, leading to increased output and higher overall productivity.

Another benefit of automatic slitting machines is improved accuracy and precision. These machines are able to make precise cuts with minimal waste, resulting in higher quality products and reduced material costs. In addition, the automation of the slitting process can help eliminate human error, leading to a more consistent end product.

Furthermore, automatic slitting machines can help companies better utilize their resources. By reducing the amount of labor required for the slitting process, companies can reallocate employees to other tasks that require more skill or expertise. This can lead to a more efficient use of labor and ultimately improve overall productivity.

In addition to the cost savings and improved output, automatic slitting machines can also help companies stay competitive in today's market. By streamlining production processes and increasing efficiency, companies can better meet customer demands for faster turnaround times and higher quality products. This can help companies attract new customers and retain existing ones, leading to increased profits and greater success in the long run.

Overall, the efficiency of an automatic slitting machine is undeniable. By automating the process of cutting materials into smaller strips, companies can achieve cost savings, improve output, and stay competitive in today's market. With the potential for significant benefits in terms of cost, quality, and productivity, it's no wonder that more and more companies are turning to automatic slitting machines to streamline their production processes.

Conclusion

In conclusion, the efficiency of an automatic slitting machine is undeniable when it comes to streamlining production processes. With its precision cutting capabilities and high speed operation, it can significantly increase productivity and reduce production time. By investing in this technology, companies can improve their overall workflow and output quality, ultimately leading to cost savings and increased competitiveness in the market. Embracing automation in manufacturing is the way forward, and an automatic slitting machine is a prime example of how innovative technology can revolutionize the industry. Make the smart choice for your business and consider integrating this efficient machine into your production line today.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.