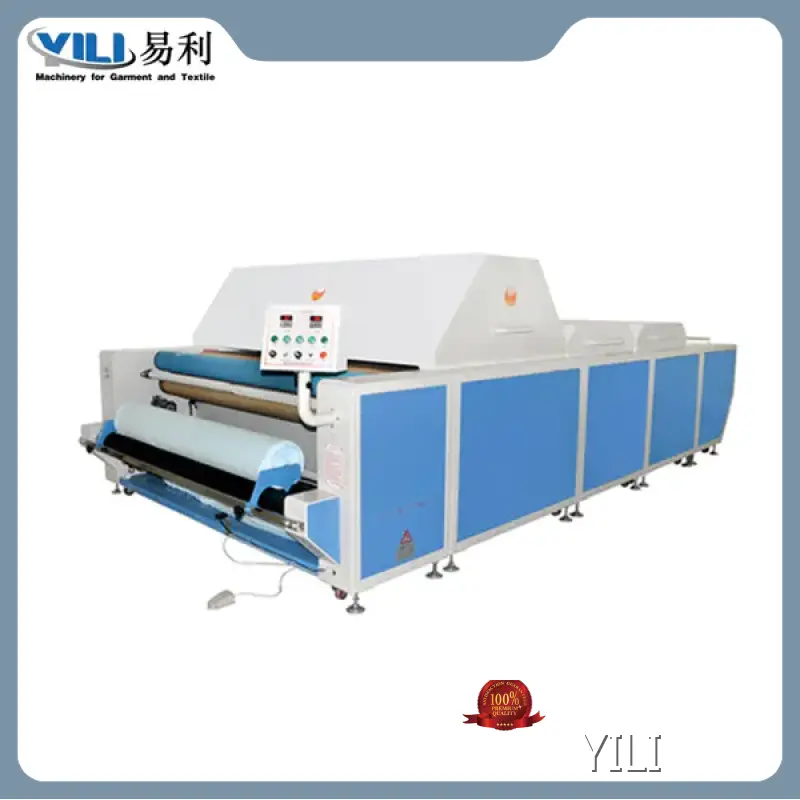

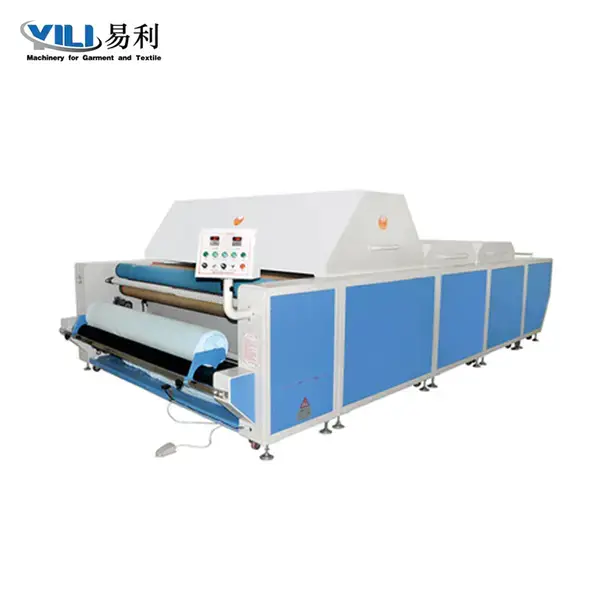

Fabric Steam Shrinking Machine by YILI-1

Product Overview

Sure! Here is a summary of the “Fabric Steam Shrinking Machine by YILI” based on the detailed introduction, organized into five key points:

Product Features

**Product Overview:**

Product Value

The Fabric Steam Shrinking Machine YL-4800 by YILI is a high-end industrial equipment designed for efficient fabric steam shrinking. It integrates steam humidification, heating, drying, fabric spreading, measuring, folding, and cooling functions into one advanced system. Suitable for knit and woven fabrics, especially pure cotton, silk, wool, and linen, it aims to stabilize fabric size while maintaining fabric quality.

Product Advantages

**Product Features:**

Application Scenarios

- Unique fully sealed steam cover with triple-layer stainless steel for heat preservation and no steam leakage.

- Steam heating as the primary drying method with electric heating as auxiliary to save energy and meet different fabric temperature needs.

- Electronic eye monitoring system ensures tension-free fabric release.

- Step-less frequency conversion timing and adjustable working speed (0-20m/min).

- Use of durable components like high-temperature resistant Teflon mesh belt and imported electrical appliances for stable performance.

- Special vibration function to keep fibers fluffy and a strong cooling device for quick fabric stabilization.

**Product Value:**

This machine reduces steam consumption by approximately 40% compared to similar products, leading to significant energy savings. The design ensures long-lasting stable operation and extended service life, minimizing downtime and maintenance costs. By maintaining fabric integrity and size stability, it enhances the overall quality of textile products, supporting eco-friendly production without harming humans or the environment.

**Product Advantages:**

- High-end market positioning with superior quality and advanced technology.

- Comprehensive multifunctional integration (humidification, heating, drying, spreading, measuring, folding, cooling, and vibration).

- Energy-efficient design with sealed steam system and dual drying sources.

- Durable and reliable components, ensuring consistent and stable performance.

- Enhanced fabric quality control with tension monitoring and quick cooling for size stabilization.

**Application Scenarios:**

Primarily used in textile manufacturing for processing various types of fabrics including knit, woven, pure cotton, silk, wool, and linen. It is ideal for factories focusing on high-quality fabric finishing processes requiring precise size stabilization and fabric quality enhancement. Suitable for industries aiming to improve fabric texture, reduce shrinkage, and maintain fiber fluffiness through controlled steaming and drying operations.

---

If you would like, I can also help in creating concise marketing or technical descriptions based on this information.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.